The Candy Packing Machine industry plays a crucial role in the modernization of confectionery production. With the increasing demand for candy products worldwide, manufacturers are adopting advanced packaging technologies to meet both efficiency and quality standards. These machines not only increase productivity but also improve packaging consistency, enhance product shelf life, and cater to consumer expectations for attractive and hygienic packaging.

The Evolution of Candy Packaging Technology

Over the past few decades, candy packaging has evolved from manual labor to highly automated, high-speed machinery. Early systems were simple hand-operated equipment, while today's candy packing machines feature complex automation, electronic controls, and innovative technologies that streamline the packaging process. These machines now provide faster, more reliable, and cost-effective packaging solutions.

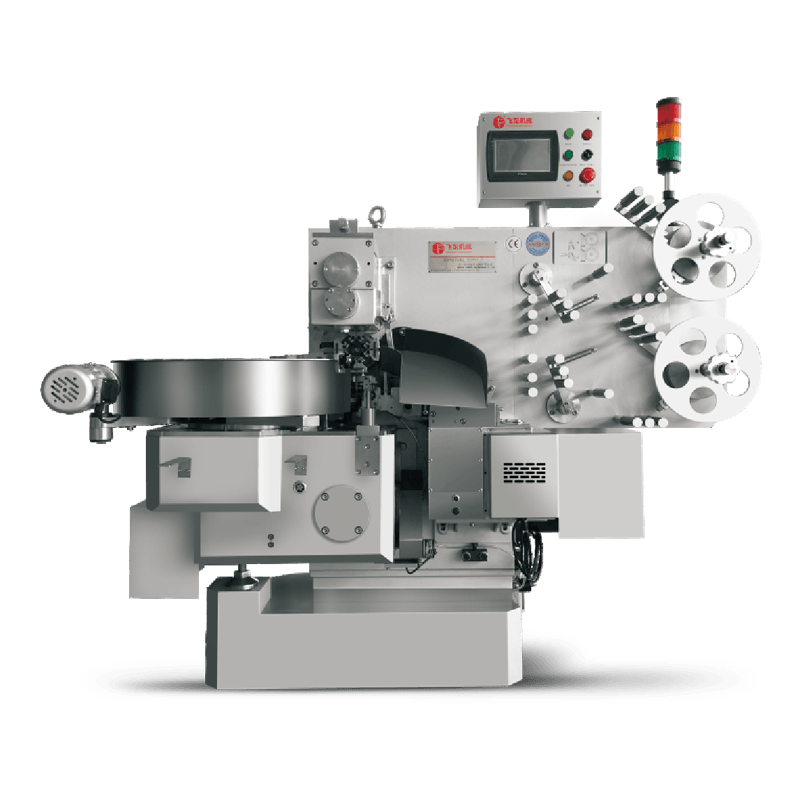

With advancements in materials and design, twist wrapping, flow wrapping, and thermoforming have become the industry standards. These methods ensure that candies are well-protected, appealing to consumers, and easy to handle during transportation and storage.

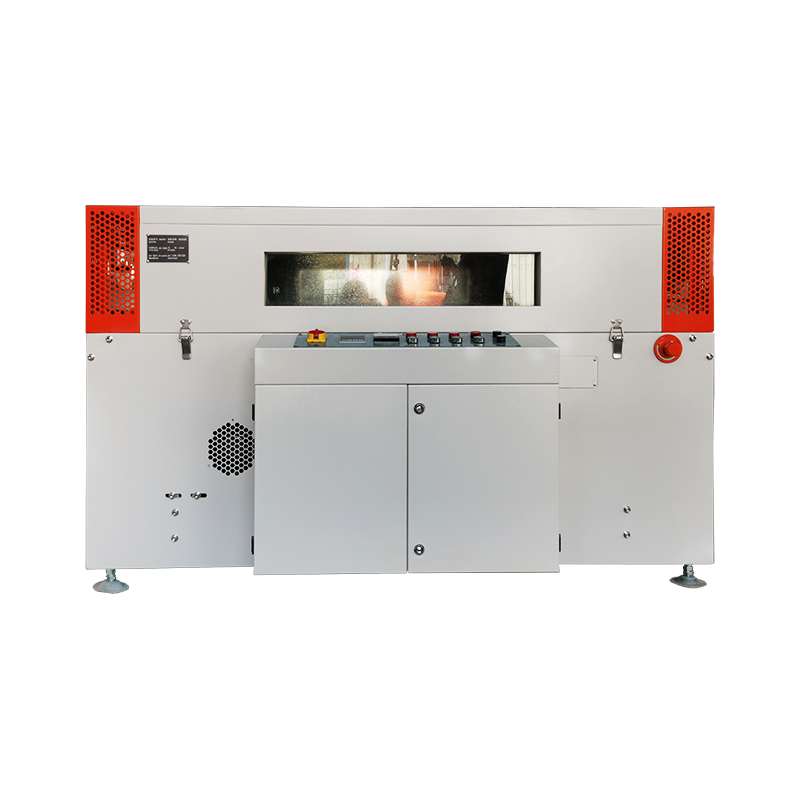

Key Features of Modern Candy Packing Machines

High-speed performance: Some models can pack up to 300 candies per minute.

Precision wrapping: Ensures uniform appearance and minimal material waste.

Multi-format capability: Suitable for different candy shapes, sizes, and packaging styles.

User-friendly controls: Most modern machines are equipped with touch screens, preset programs, and fault alarms.

Customization support: Options for logo printing, barcoding, or labeling.

How Candy Packing Machines Support Growth, Brand Image, and Profitability

Candy packing machines are the engine behind operational success in the confectionery business. By automating the packaging process, they:

Increase production speed, enabling startups to fulfill more orders with fewer employees.

Ensure consistency in every unit, building trust with customers and retail partners.

Reduce material waste and human error, improving margins and operational control.

Enable diverse packaging options, allowing for seasonal offerings, gift boxes, or multipacks.

Support scalability, making it easy to increase output as demand grows.

Most importantly, automated packaging helps startups present themselves as professional, reliable brands—key attributes in gaining retail shelf space, securing investment, and building a loyal customer base.

Flyloong's Role in the Candy Packaging Industry

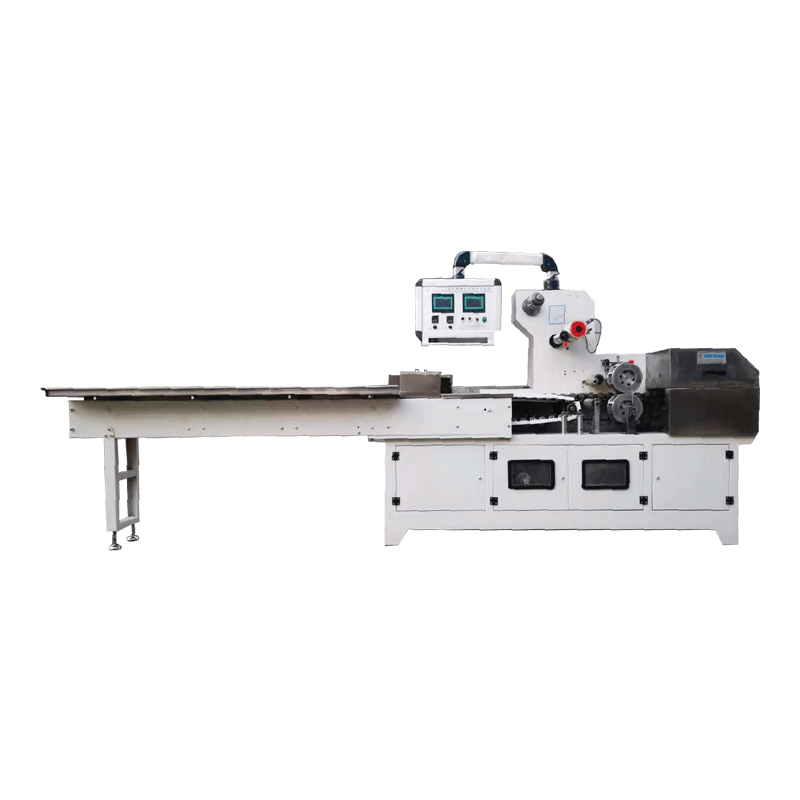

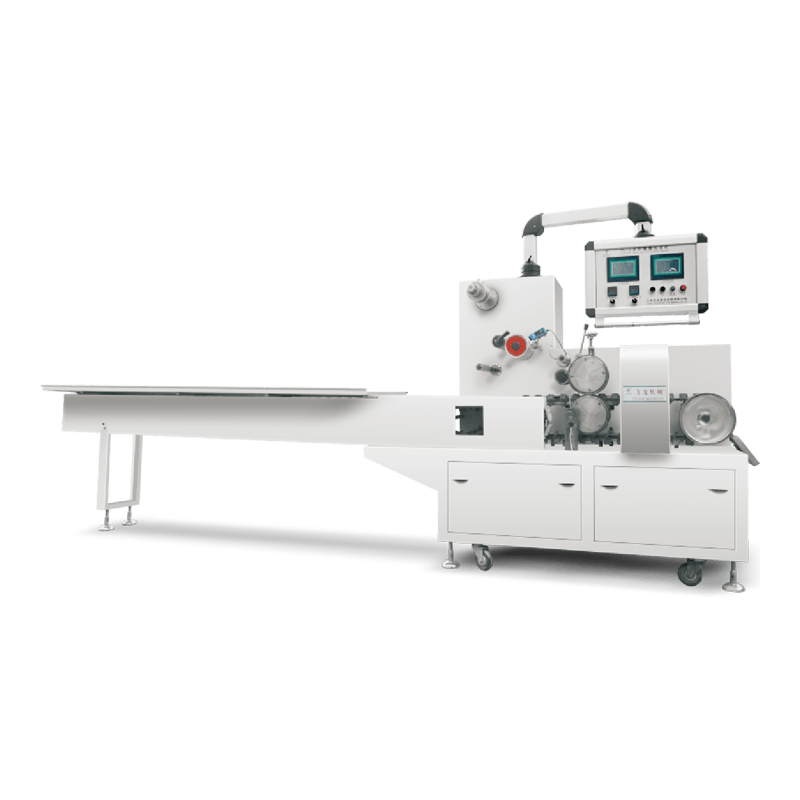

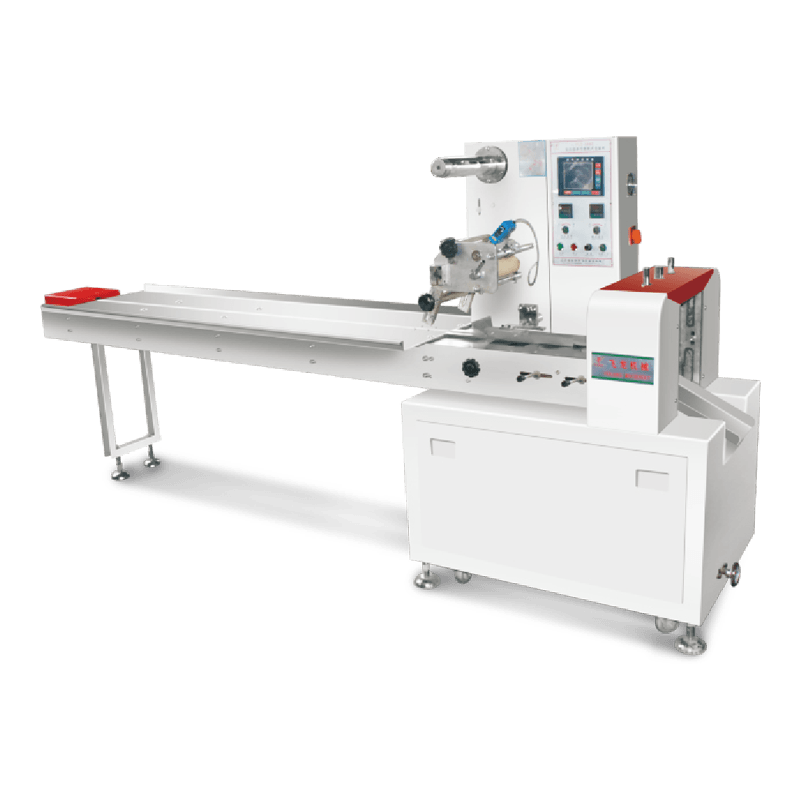

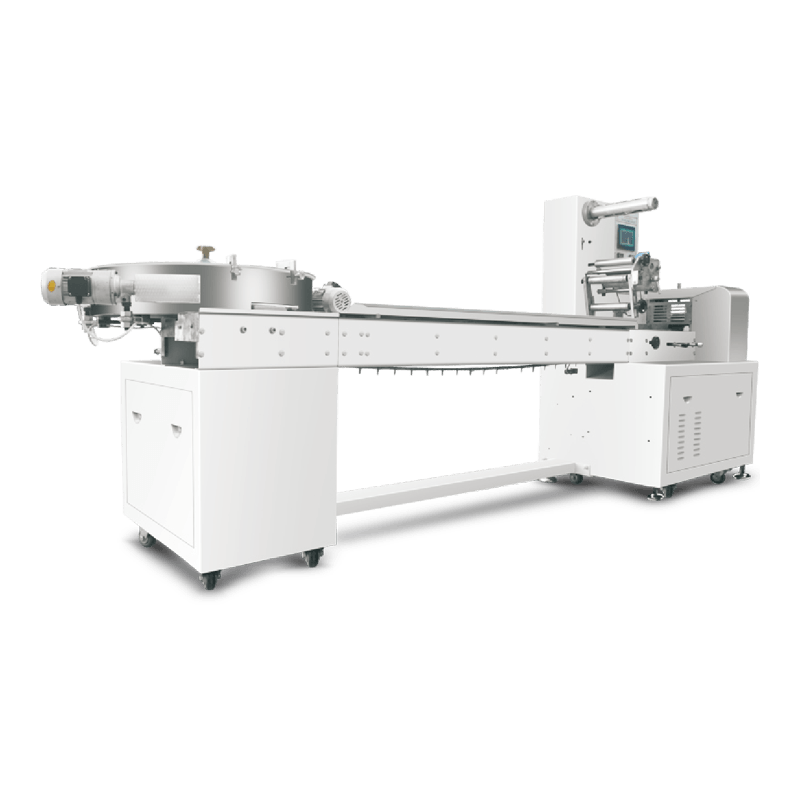

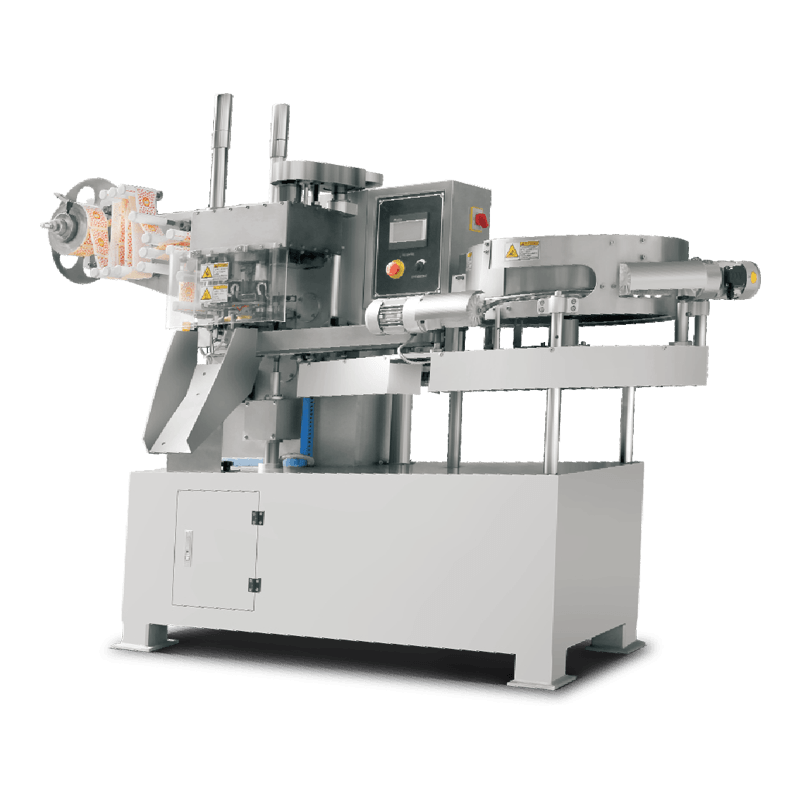

At Flyloong Candy Machine Factory, we are committed to providing innovative solutions for the candy packaging industry. Our advanced machines, such as the FLD-Air Press Twist Packing Machine, deliver exceptional performance in packaging efficiency, quality, and flexibility. Whether you're a small-scale artisan candy maker or a large confectionery manufacturer, our solutions are tailored to meet your unique production needs.

Our machines are designed to integrate seamlessly with existing production lines, providing users with reliable, efficient, and customizable packaging solutions that ensure top-quality results every time.

The candy packing machine industry continues to evolve, driven by technological advancements and changing market demands. With the right machinery, manufacturers can not only meet these demands but also achieve significant improvements in production efficiency, packaging quality, and overall profitability.

At Flyloong Candy Machine Factory, we pride ourselves on offering cutting-edge machines that stay ahead of industry trends and provide our clients with packaging solutions available. Whether you need high-speed packaging, sustainable materials, or custom designs, we have the expertise and equipment to meet your needs.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home