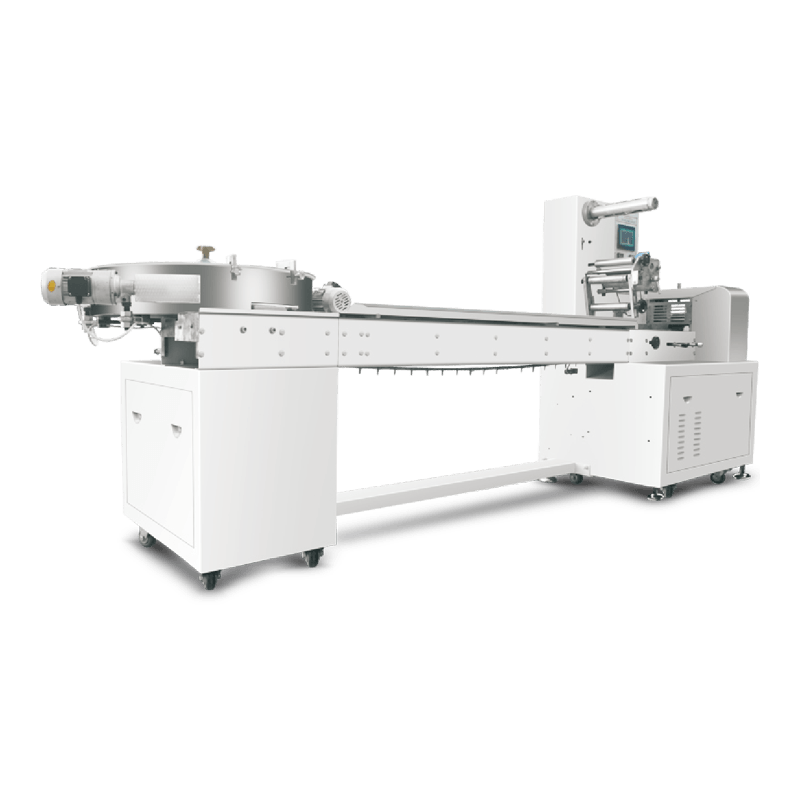

This machine is designed to streamline the packaging process while maintaining product integrity and ensuring minimal waste. The FLD-988E combines advanced technology, ease of use, and low maintenance, making it an ideal choice for high-volume production lines in the food industry.

Key Features:

Versatile Packaging for Various Candy Shapes:

The FLD-988E is capable of packing different candy shapes, such as square, spherical, circular, cylindrical, button, oval, and many other custom shapes. Its flexible design accommodates various product types, ensuring versatility for diverse packaging needs.

Innovative and Reliable Structure:

With a novel structure, the FLD-988E ensures smooth operation and a low failure rate, even under continuous use. The design minimizes the chances of mechanical issues, ensuring reliable performance throughout the production process.

Intelligent Control System:

The FLD-988E is equipped with an LCD display computer control system, allowing for easy operation and setting adjustments. The photoelectric color standard sensor ensures accurate detection and bidirectional tracking, preventing errors in packaging. This advanced control system also helps in fast tracking and eliminates packaging errors, minimizing material waste.

Precise Temperature Control:

The machine includes an intelligent temperature controller for accurate temperature regulation. It features a straight display view for convenient monitoring and adjustment, ensuring optimal sealing and packaging conditions for various products.

Stainless Steel Contact Parts:

All food-contact parts of the machine are made from high-quality stainless steel, offering smoothness and easy cleaning. This ensures compliance with food hygiene standards and makes the machine suitable for use in the food industry, maintaining product safety and cleanliness.

Adjustable Feeding Position:

The FLD-988E features a rotating feeding position adjusting device that allows for easy adjustments without needing to stop the machine. This feature enables seamless operation and increases productivity by reducing downtime.

Low Noise Operation:

Designed with a focus on minimizing noise, the FLD-988E operates quietly, improving the working environment and providing a more comfortable operation for factory staff.

|

Production capacity (Pieces/minute)

|

200-600

|

|

Packing dimension

|

Length 15-40; Width 12-25; Thickness 6-16

|

|

Total power

|

3.5kW

|

|

External dimensions

|

3800×900×1600

|

|

Weight

|

1100kg

|

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

Capacity

|

|

FLD-988E Automatic

Pillow Packing Machine

|

3.7

|

1000

|

2900*1305*1586

|

200-600

pieces/minute

|

Technical Specifications:

Candy Shapes: Square, spherical, circular, cylindrical, button, oval, and special shapes

Control System: LCD display computer control with photoelectric color standard sensor

Temperature Control: Intelligent temperature controller with accurate regulation

Material: Stainless steel food contact parts for easy cleaning and hygiene

Feeding Position Adjustment: Rotating device with no need to stop the machine for adjustments

Noise Level: Low noise operation for a comfortable working environment

Advantages:

High Efficiency and Precision:

The FLD-988E ensures high-speed and accurate packaging, minimizing downtime and material waste. The precise temperature control and photoelectric detection ensure that each product is perfectly sealed and packaged.

Versatility for Various Product Shapes:

This machine is highly versatile, making it suitable for a wide range of candy shapes, from square and cylindrical to more complex, custom shapes. It offers flexibility in your packaging needs, allowing manufacturers to easily switch between product types.

Low Maintenance and Long-Term Reliability:

Built with a low failure rate and easy-to-maintain components, the FLD-988E is designed for long-term use in high-volume production lines. Its innovative design reduces wear and tear, ensuring reliable performance over time.

Improved Hygiene Standards:

The stainless steel contact parts not only ensure smoothness but also make the machine easy to clean, helping businesses maintain hygiene standards and comply with food safety regulations.

Minimized Packaging Errors and Waste:

The photoelectric color standard sensor and bidirectional tracking system effectively eliminate errors in packaging, preventing waste and ensuring accurate patterning. This precision enhances the overall efficiency of your production line and reduces material costs.

Applications:

The FLD-988E Pillow Packing Machine is widely used in the confectionery industry and is suitable for packing a variety of products, including:

Candies (square, spherical, cylindrical, button, oval, and custom-shaped)

Chocolates

Snack foods

Other solid-state products with defined shapes

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home