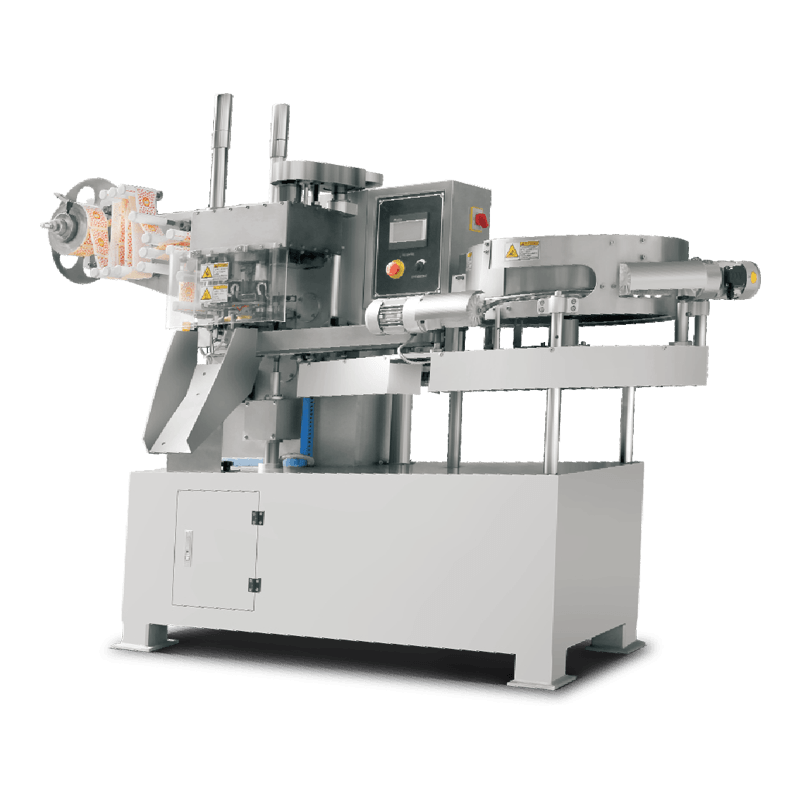

The FLD-Ball Lollipop Packing Machine is a highly efficient and reliable solution designed specifically for packing spherical lollipops. Featuring advanced technology and a user-friendly design, this machine offers smooth, stable operation with minimal noise, ensuring an ideal packaging process for lollipops while meeting both performance and hygiene standards.

Key Features:

Spherical Lollipop Packaging:

The machine is tailor-made for packaging spherical lollipops, featuring an automatic sugar feeding system and an innovative design that guarantees precise wrapping. Its stable performance and low noise operation make it a reliable choice for high-volume production lines.

Stepless Variable Speed Control:

Equipped with an AC motor and frequency converter, the machine enables stepless variable speed control, providing flexibility in production speed. This feature ensures that the machine can adapt to different production needs, enhancing efficiency and control.

Intelligent Computer Control:

The FLD-Ball Lollipop Packing Machine features automatic computer control with a photoelectric color standard tracking system. This system ensures that the wrapping process is precise, and the colors align correctly, avoiding packaging errors and material waste.

Advanced Photoelectric Detection:

Utilizing internationally advanced photoelectric sensor detection, the machine offers two-way tracking with fast, accurate pattern recognition. This technology significantly improves packaging accuracy, ensuring that the wrapped lollipops are sealed neatly and consistently.

Sanitary Design and Easy Maintenance:

Food contact parts of the machine are made from high-quality stainless steel, ensuring durability, smoothness, and easy cleaning. This design meets stringent hygiene standards, making the machine suitable for food-grade applications.

Machine Components:

The FLD-Ball Lollipop Packing Machine is equipped with several key components to ensure efficient and accurate packaging:

Automatic Sorting Device: Ensures smooth candy alignment for accurate packaging.

Color Code Auto Tracking System: Automatically adjusts to align wrapping paper with the candy, ensuring consistency and precision.

Standard Tongs and Lollipop Conveyor Chain: Move candies smoothly through the machine without damaging them.

Packing Device & Heat Sealing Knotting Device: These components seal the lollipops securely, preventing any leakage or contamination.

Rotating Plate Device: Facilitates easy paper feeding and smooth wrapping.

Performance Benefits:

Efficient Operation and High Output:

The FLD-Ball Lollipop Packing Machine significantly reduces labor costs by automating the packing process. It not only increases the production speed but also improves the consistency and quality of the packaging, leading to higher production efficiency.

Improved Sanitation and Quality Control:

With stainless steel parts and a well-designed structure, the machine ensures compliance with food hygiene standards, maintaining high sanitation levels throughout the packaging process. The result is clean, well-sealed, and attractive lollipop packages.

Accurate and Reliable Wrapping:

The machine's color code tracking system and photoelectric tracing circuit ensure precise wrapping. Even if there is a paper issue or a curled wrapper, the machine adjusts automatically, eliminating waste and ensuring that each candy is packed correctly.

Easy Operation and Maintenance:

The PLC control system, along with features like a man-machine interface, makes the machine easy to operate. The rotary encoder and photoelectric switches further enhance performance, while the modular design allows for easy maintenance and quick repairs.

|

Power of main motor

|

0.75kw 380v

|

|

Power of brushing motor

|

4×60w 380v

|

|

Power of paper feeding motor

|

0.2kw 220v

|

|

Heating sealing pipe

|

0.15kw×6 24v

|

|

Air pressure

|

0.2-0.5Mpa

|

|

Output (According to standard shape candy)

|

1000-2000kg/8h

|

|

External dimensions (mm)

|

2500×900×1500

|

|

Weight (kg)

|

1200

|

|

Machine Name

|

Power

|

Spherical diameter(mm)

|

Dimension (mm)

|

Capacity

|

Packaging film materials

|

|

FLD-Ball lollipop

packing machine

|

2.1

|

20-35

|

2500*900*1500

|

10-130 grains/minute

|

BOPP compounded with CPP, PET compounded with

OPP and various composite films, etc.

|

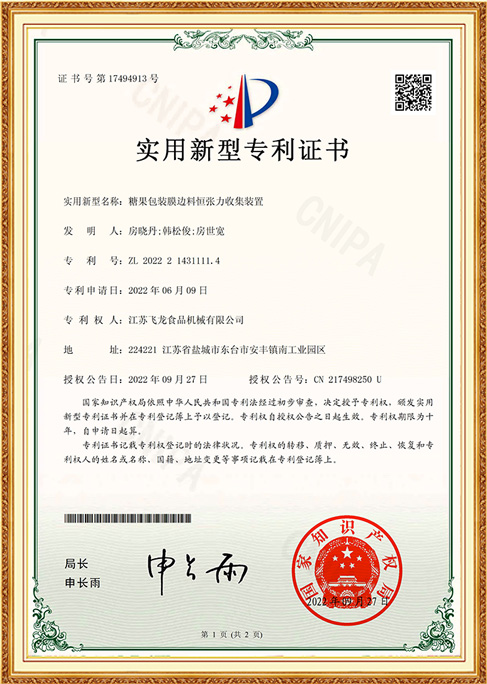

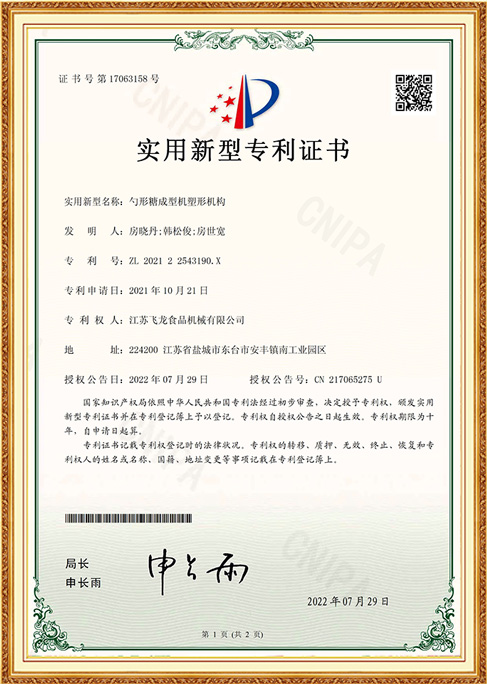

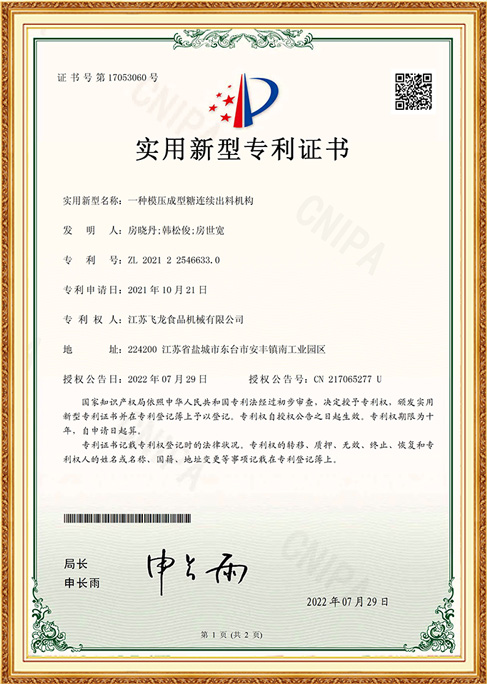

Why Choose FLD-Ball Lollipop Machinery from Flyloong Factory?

The FLD-Ball Lollipop Machinery from Flyloong Factory is designed to meet the packaging needs of spherical lollipops with precision, efficiency, and reliability. Here are some reasons to choose this machine for your production line:

High Efficiency:

The FLD-Ball Lollipop Machinery offers high-speed packaging, allowing you to pack a large volume of lollipops quickly and efficiently. This boosts production capacity and reduces labor costs.

Advanced Technology:

Equipped with automatic computer control, photoelectric color tracking, and stepless variable speed control, the machine ensures precise and consistent wrapping, minimizing errors and material waste.

Durable and Hygienic Design:

Made with stainless steel food contact parts, the machine is easy to clean and complies with food hygiene standards. It’s designed to provide long-lasting performance with low maintenance needs.

User-Friendly Operation:

With a simple interface and PLC control system, the machine is easy to operate, allowing for quick setup and adjustments. The intuitive design reduces training time for your staff.

Versatility and Customization:

Ideal for spherical lollipops and other solid candy products, the machine can be adapted to meet different production needs, offering flexibility in packaging.

By choosing Flyloong's FLD-Ball Lollipop Machinery, you're ensuring a reliable, high-performance packaging solution that will enhance the efficiency, quality, and cost-effectiveness of your candy production process.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home