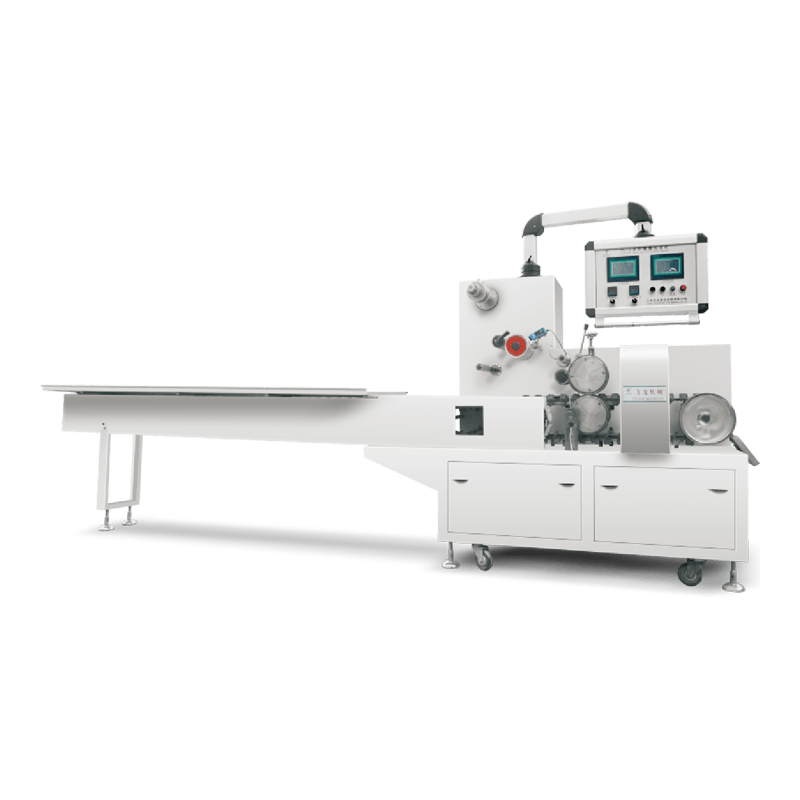

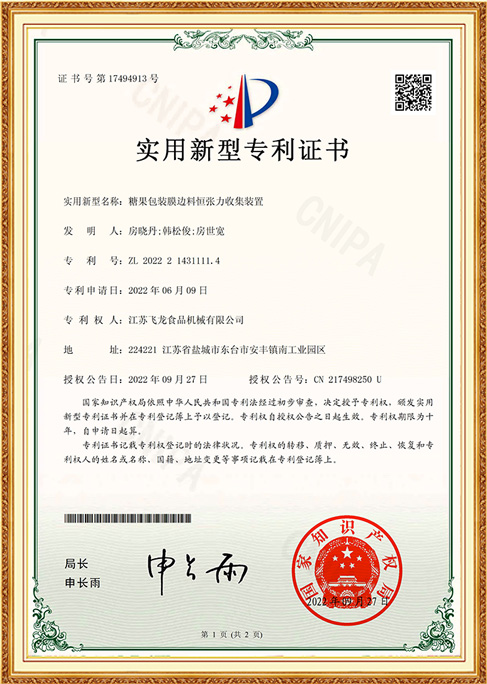

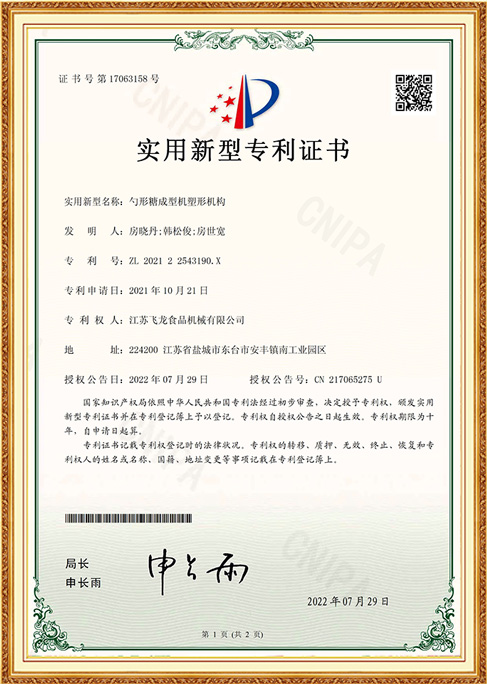

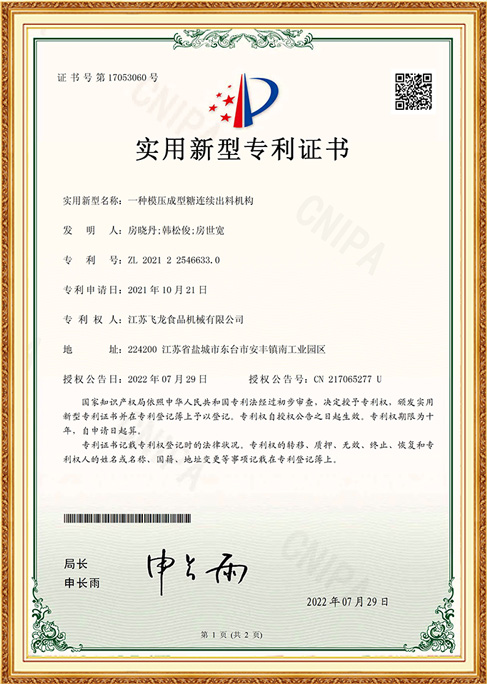

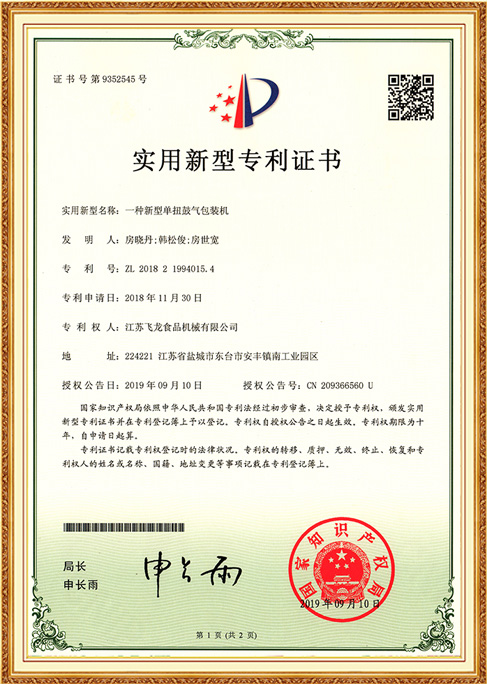

The machine is suitable for all kinds of flat special-shaped lollipops double-layer film densePackaging machinery, with ascendant performance, smooth operation,Reliable, the packaging products beautiful appearance generous, good sealing performance,Long storage time and other characteristics. Using photoelectric tracking paper cutting, structureNovel, easy to operate and other advantages, is a variety of special-shaped lollipop packagingThe ideal equipment .“New Patented Products by the State.

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

Capacity

|

|

FLD- Hand row four side

packing machine

|

8

|

1000

|

4400*1050*1700

|

60-280

pieces/minute

|

Why Flyloong Lollipop Packaging Machine Stands Out

Our spherical lollipop head packaging machine is designed with both efficiency and user-friendliness in mind.

Our machine automatically feeds sugar and works quietly with a modern, neat design. It's built for stable performance and easy maintenance, so you don't have to worry about downtime.

Equipped with an AC motor and frequency converter, you can adjust the speed smoothly and precisely to match your production needs.

Our machine is computer-controlled with photoelectric color tracking, ensuring consistent quality with minimal human intervention.

Our machine using international-standard photoelectric sensors and two-way tracking, it follows patterns quickly and accurately, keeping your products uniform and professional.

Our machine's all parts that touch food are made of stainless steel, making cleaning simple and meeting strict hygiene standards.

Flyloon's machine is efficient, reliable, and built with real production needs in mind, helping candy manufacturers save time, reduce waste, and maintain consistent quality.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home