Understanding Candy Machine and Their Role in Consistent Production

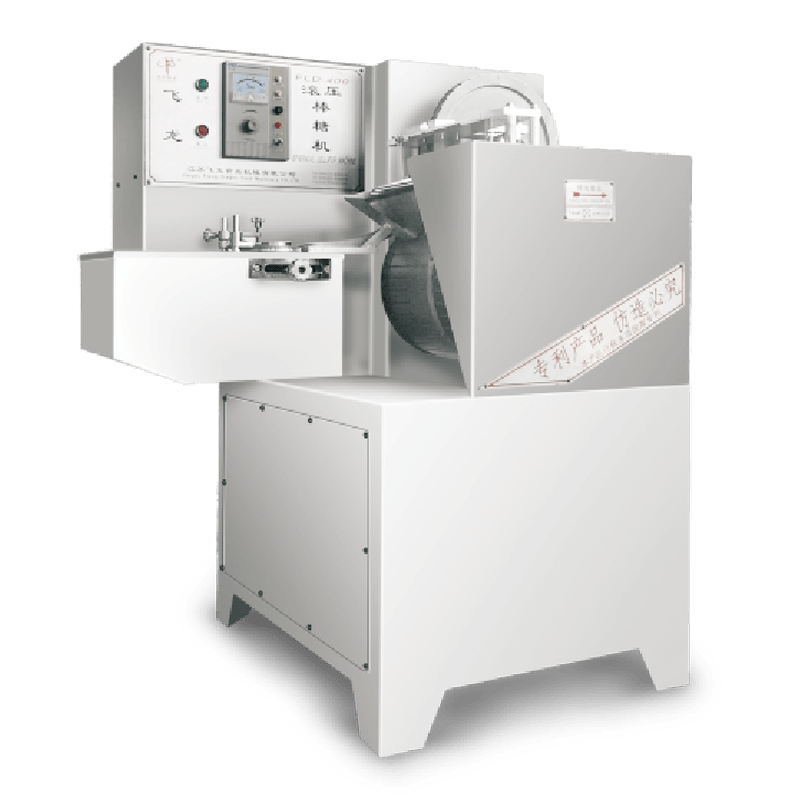

Making candy can be fun, but it also needs to be handled carefully. The use of the right machines, such as the Milk Candy Machine, helps to make the production smoother, to maintain the consistency of the sweets, and to make sure that each batch is the same.

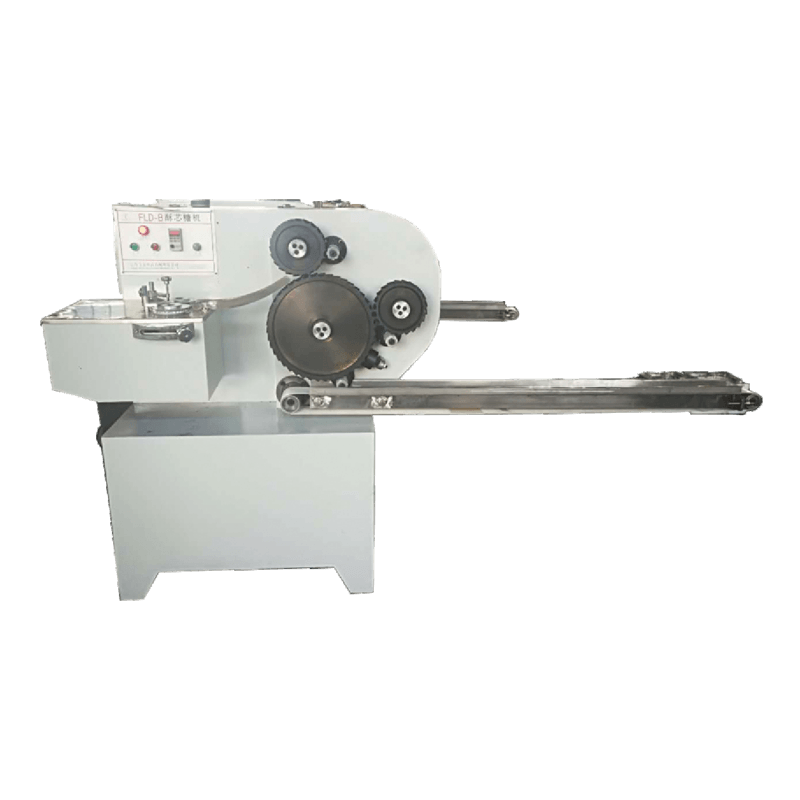

1. Forming Candy

Forming machines give candy its shape. Things like temperature, speed, and mold type all affect the result. If the line moves too fast, candy can crack or come out uneven. Learning how to adjust these settings helps produce candies that are the same size and shape every time.

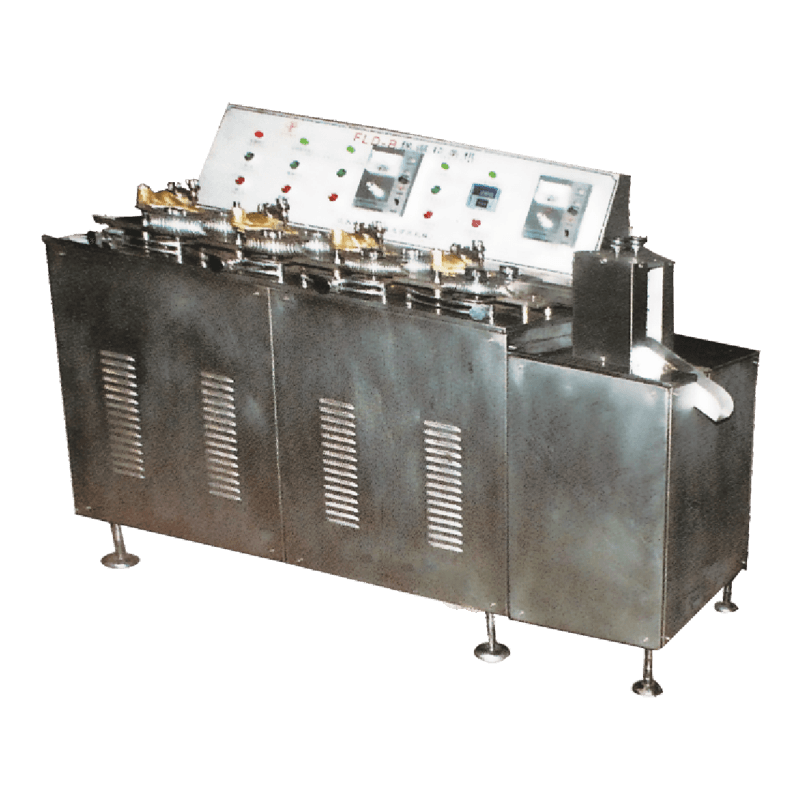

2. Cooling Candy

Candy needs to cool before packaging. Cool it too fast, and cracks can appear; cool it too slowly, and it may stick together. Using the right cooling equipment helps candy keep its shape and texture. Knowing the right speed for different candies makes a big difference.

3. Layers and Colors Adding Colors

Some machines, such as the Milk Candy Machine, are capable of processing multiple colors or layers at once. This allows for candies with stripes, patterns, or fillings. Controlling timing and color flow is important to get consistent and attractive results.

4. Keeping Production Smooth

Machines can run continuously, which helps factories keep production steady. Learning how to balance speed with batch size reduces errors and improves workflow efficiency.

5. Maintenance Matters

Regular cleaning and easy maintenance keep the machine working reliably. Well-maintained equipment prevents downtime and helps candies stay uniform in quality.

Quick Tips for Beginners

- Match machine settings to the type of candy.

- Test cooling and forming before running a full batch.

- Plan production to avoid mixing colors or flavors.

- Keep notes of settings that worked well for repeatable results.

By knowing how the candy machine works and how it works, including the Milk Candy Machine, you will be able to produce more consistent candy, less waste, and better understand why every step of the production process is important.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home