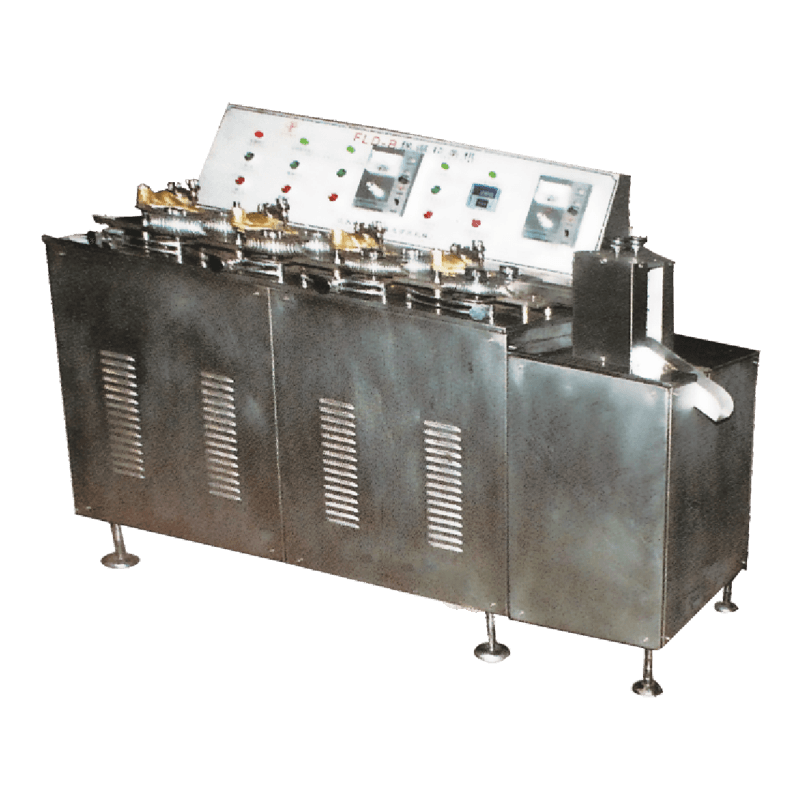

The FLD-B Hard Candy Rolling Cutting Machine by Flyloong is specifically designed to efficiently produce a wide variety of fancy candies, including those with diameters ranging from Φ25mm to Φ35mm. Whether you're in the food manufacturing industry or looking to expand your confectionery production, this machine is an essential tool that guarantees high efficiency and consistent product quality. The FLD-B Rolling Cutting Machine features cutting-edge technology, durability, and ease of use, making it an ideal choice for candy producers worldwide.

This series is suitable for the production of Φ25mm-Φ35mmAll kinds of fancy candy.

Key Features of the FLD-B Hard Candy Rolling Cutting Machine

High Production Capacity

The FLD-B Rolling Cutting Machine is capable of processing large volumes of hard candy, with consistent and uniform production of candies in the size range of Φ25mm to Φ35mm. This high output ensures maximum production efficiency, even in large-scale operations.

Powerful Performance

Equipped with a 3.3 kW motor, the machine delivers strong, reliable performance that ensures smooth and continuous operation, even with high-density candy materials. The motor is designed to handle extended periods of operation without compromising on quality or efficiency.

Precise Cutting and Shaping

With its advanced cutting and rolling mechanism, the FLD-B Hard Candy Rolling Cutting Machine guarantees precise shaping of candies, with accurate and clean cuts. The uniformity of candy size and shape enhances product quality and ensures that every piece meets production standards.

Compact and Robust Design

The FLD-B Rolling Cutting Machine is built to last, featuring a sturdy design that can withstand high-demand production environments. With dimensions of 1400mm x 800mm x 1300mm and a weight of 430 kg, this machine is compact enough to fit in most production spaces while offering durability and stability.

User-Friendly Interface

Designed with ease of operation in mind, the FLD-B Rolling Cutting Machine features a user-friendly interface. Operators can easily adjust settings, ensuring that the machine runs efficiently with minimal downtime and maintenance. This design reduces training time and enhances productivity.

Low Maintenance Requirements

The machine is built with minimal maintenance in mind. Its robust construction and durable components ensure long-lasting performance, while its simple design makes it easy to maintain and clean. This reduces downtime and ensures a consistent production output.

Flexible Application

The FLD-B Hard Candy Rolling Cutting Machine is ideal for producing a variety of fancy candies, including those of different shapes and sizes. This flexibility makes it suitable for various applications in the candy industry, including special-shaped candies, fruit-flavored candies, and more.

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

|

FLD- B Rolling Cutting Machine

|

3.3

|

430

|

1400*800*1300

|

Why Choose the FLD-B Hard Candy Rolling Cutting Machine by Flyloong?

Efficient and High Capacity Production

The FLD-B Rolling Cutting Machine ensures high output and efficient candy production, reducing operational costs and increasing overall production efficiency.

Precision and Consistency

With its advanced cutting mechanism, this machine guarantees uniform size and shape, enhancing the presentation and marketability of your products.

Reliable and Durable

Built to last with high-quality components, the FLD-B Hard Candy Rolling Cutting Machine provides long-term, trouble-free performance, even under heavy use.

Space-Saving Design

Despite its robust capabilities, the FLD-B Rolling Cutting Machine features a compact design that can easily fit into most candy production lines without taking up excessive space.

Low Maintenance

This machine is designed for minimal maintenance. With its easy-to-operate features and durable construction, it helps reduce downtime and service costs, allowing for consistent production.

Versatility in Candy Production

The machine can handle a wide range of candy types, from traditional hard candies to more complex designs, offering flexibility for candy producers looking to diversify their product offerings.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home