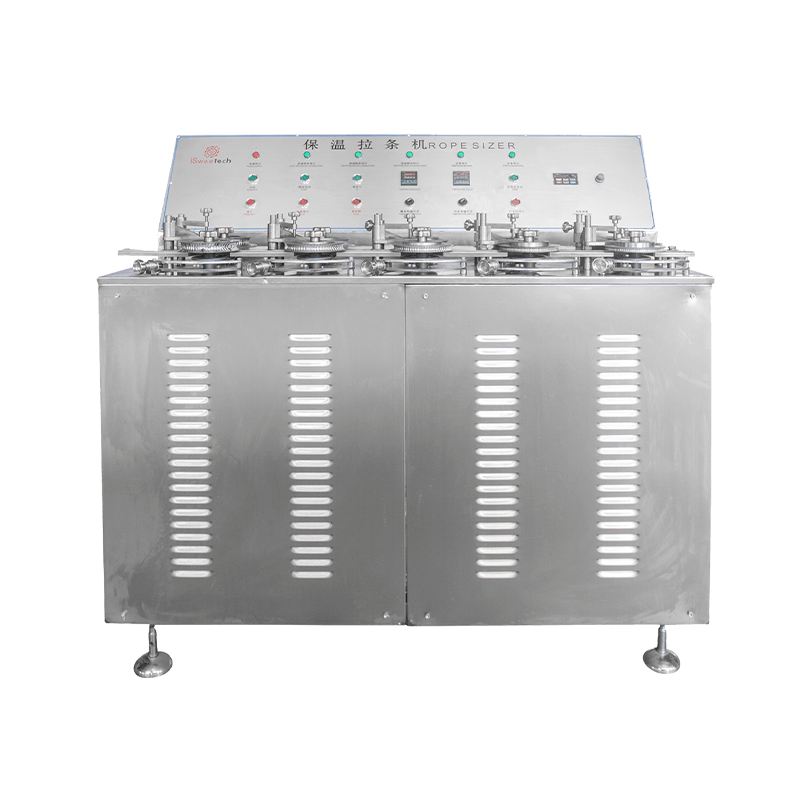

The Candy Rope Sizer is a crucial component in the candy manufacturing process. Designed to shape and size candy ropes, it works by pulling batches of candy from a Candy Batch Roller and calibrating the rope to the required size before further candy formation.

Machine Structure and Functionality

The machine consists of four pairs of horizontally arranged sizing rollers. Each pair of rollers features holes with different diameters (20 mm, 16 mm, 14 mm, and 12 mm) and varying linear speeds, ensuring that the candy rope is progressively stretched and reduced in diameter.

Standard Size: The machine typically reduces the candy rope to a 12 mm diameter, which is ideal for most candy production needs.

Customization: Upon request, the machine can be modified to produce candy ropes with smaller diameters, such as 10 mm or 8 mm.

Adjustable Speed Control

To accommodate varying production requirements, the Candy Rope Sizer comes with an adjustable rotation speed. This allows manufacturers to control the pace of the candy rope sizing process and ensure consistent output.

Optional Cutting Unit

The machine can be equipped with a Cutting Unit, which is designed to cut the candy rope into uniform pieces of the desired length, ranging from 5 cm to 25 cm. These uniform pieces can then be used for the formation of various types of candies, including candy canes, lollipops, twisted candies, and chopped candies.

Standalone or Integrated Solution

The Candy Rope Sizer can operate as a standalone unit or as part of a complete candy production line. When combined with a Candy Batch Roller and a Cushion Cutter/Forming Machine, it forms a compact and highly efficient production line for both soft and hard caramel production.

The Candy Rope Sizer is an essential machine for manufacturers seeking to achieve precise candy sizing and high production efficiency. Whether used independently or as part of a full production system, this machine ensures smooth operation and high-quality results.

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

|

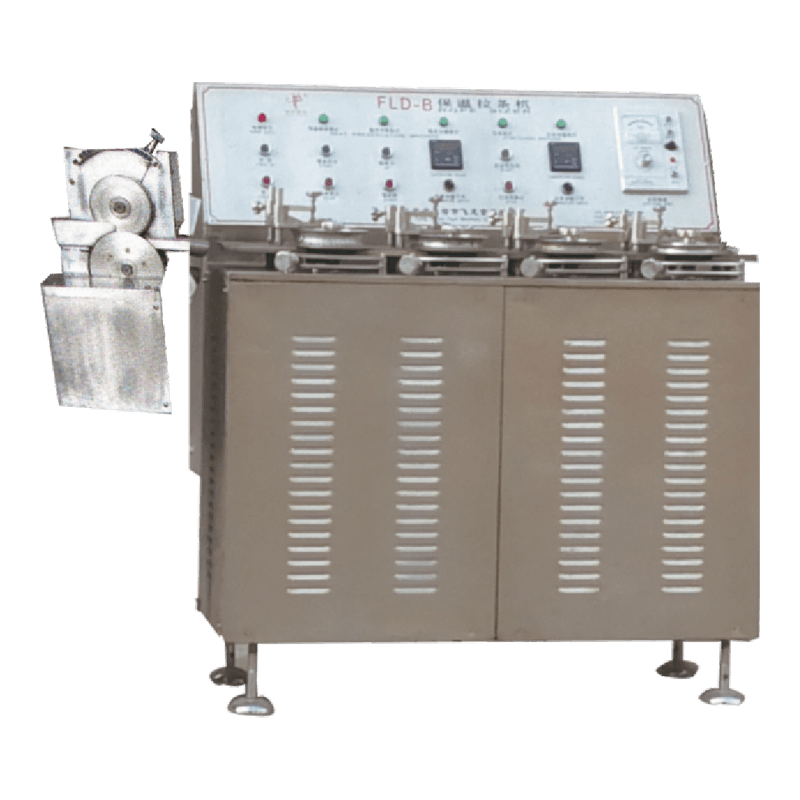

FLD- B Rolling

Cutting Machine

|

3.3

|

550

|

1500*800*1300

|

Applications of FLD-Five Rollers Rope Sizer

Candy Rope Shaping

The primary application of the FLD-Five Rollers Rope Sizer is to shape the candy ropes coming from a Batch Roller into a uniform size. It ensures consistent rope diameter, ideal for making candies of precise and uniform shapes.

Hard and Soft Candy Production

This machine is widely used in both hard and soft candy production, including caramel and taffy. By adjusting the roller size and speed, manufacturers can tailor the rope size to match the specific requirements of different types of candy.

Candy Cane Manufacturing

The FLD-Five Rollers Rope Sizer is instrumental in the production of candy canes, as it helps form the long, consistent ropes that are later twisted and cut into the familiar shape of candy canes.

Lollipop Production

In lollipop production, the machine ensures that the candy ropes are shaped to the correct thickness before they are cut into individual pieces and inserted onto sticks. This ensures the lollipops are uniform in size and shape.

Twisted Candy Production

For twisted candies, the uniform candy ropes produced by the Rope Sizer are ideal for creating the characteristic twists in candy bars, making it a vital tool for producers of high-quality twisted confections.

Chopped Candy Production

The machine can be equipped with a cutting unit to form chopped candies, ensuring the candy ropes are precisely cut into small, uniform pieces. This makes the FLD-Five Rollers Rope Sizer useful in the production of various hard candies, including chunked or chopped varieties.

Custom Candy Shaping

The FLD-Five Rollers Rope Sizer can also be customized for producing a variety of special-shaped candies. By adjusting the size and consistency of the ropes, manufacturers can create unique confections in a range of shapes and sizes.

Candy Production Lines

As part of a complete candy production system, the FLD-Five Rollers Rope Sizer is used alongside other machines such as the Batch Roller and Cushion Cutter/Forming Machine to create an integrated and efficient line for producing high volumes of candy.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home