Candy Batch Roller: Essential Equipment for Efficient and Consistent Candy Production

In the ever-evolving confectionery industry, ensuring the production of high-quality, consistent, and precisely shaped candies is essential for success. The Candy Batch Roller plays a critical role in this process, acting as a cornerstone in the preparation and shaping of candy masses. Whether you're producing hard candies, gummies, or chewy sweets, a reliable batch roller is indispensable in transforming raw sugar syrup into candy texture.

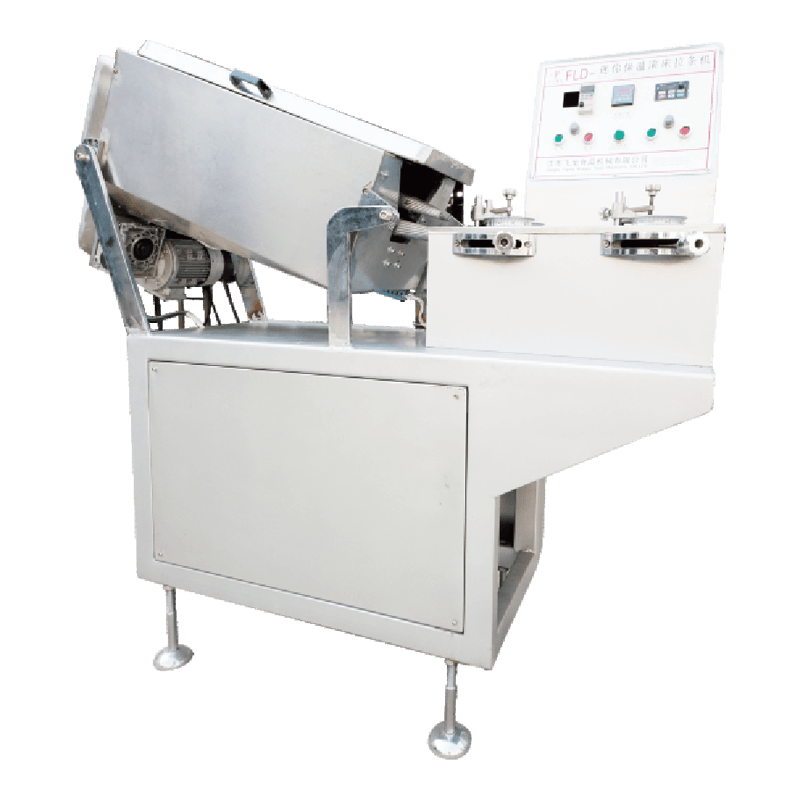

A Candy Batch Roller is an essential piece of confectionery equipment used for mixing, kneading, and shaping the candy mass in preparation for further processing. This machine helps in forming uniform batches of candy dough, ensuring consistent texture and quality across large-scale production.

The roller works by gently kneading the candy mass to the correct consistency, distributing ingredients evenly and preparing the mixture for molding or cutting. Whether you're working with hard candy, chewy confections, or specialty items like lollipops, the Candy Batch Roller ensures smooth, even texture throughout the production process.

The Candy Batch Roller typically works by feeding the prepared candy mass (which may include sugar syrup, flavorings, and colorants) into a series of rollers. The machine uses a combination of pressure, speed, and temperature control to knead and mix the ingredients to a smooth, homogenous consistency.

Feeding: The candy mass is initially fed into the rollers, often coming from a cooking unit where sugar and other ingredients are heated and mixed.

Mixing and Kneading: As the mass passes through the rollers, it is kneaded to remove any air pockets, ensuring a smooth texture. This step is critical for achieving the right consistency, especially for chewy or filled candies.

Shaping and Cooling: The mass can be shaped into the desired form before being cooled and prepared for further molding or cutting. Depending on the design, the roller may also be used to prepare a batch for specific molding equipment.

Batch Release: Once the candy mass has reached the correct consistency, it is released into the next step of the production process, such as cooling or shaping.

Why Your Business Needs a Candy Batch Roller

Investing in a Candy Batch Roller is an essential step for any candy manufacturer looking to scale up operations while maintaining high-quality standards. These machines are designed to:

Maximize production efficiency by minimizing downtime and automating key processes.

Ensure product consistency with every batch, critical for maintaining consumer trust and brand reputation.

Reduce labor costs, allowing staff to focus on other areas of the production process while the machine handles mixing and kneading.

Enhance flexibility, as batch rollers can be easily adjusted to handle different candy recipes and production requirements.

Whether you're an established brand or a startup looking to optimize your candy-making process, the Candy Batch Roller is a pivotal investment for long-term success.

The Candy Batch Roller is more than just a piece of equipment—it's a crucial factor in achieving precision, consistency, and quality in candy production. By ensuring that each batch is mixed and kneaded to perfection, it helps manufacturers streamline their production process, reduce costs, and maintain high standards across every batch.

By investing in a high-quality Candy Batch Roller, you set your candy manufacturing business up for success, allowing you to meet growing demand and deliver a superior product to consumers.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home