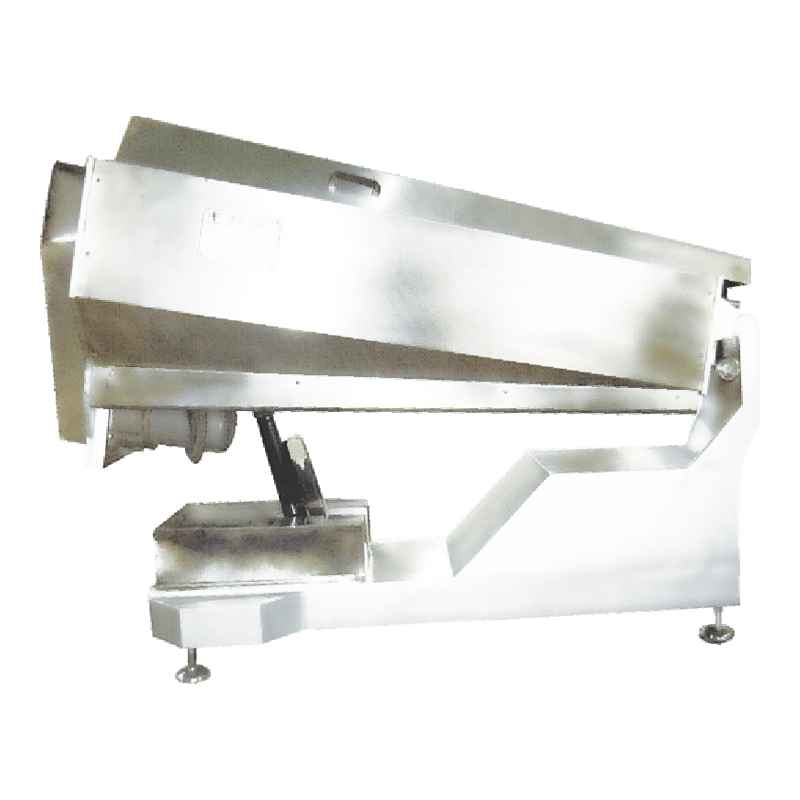

The batch roller is a good machine for coffee, caramel, fruit chew, or high-boiled hard candy to shape the batch into a rope. It consists of four rotating rollers which change the rotating direction automatically after a fixed number of rotating. For heating the roller we used an electric heater. The machine is controlled by electric penal. It has a downjack system, and can also be connected with a powder and jam feeder.

Key Features of the FLD-B Batch Roller:

Efficient and High-Speed Operation:

The FLD-B Batch Roller is designed for high-efficiency production, offering a speed range of 30-45 revolutions per minute (RPM). This speed ensures rapid processing of batches, making it suitable for large-scale manufacturing environments that require high throughput.

Precise and Uniform Rolling:

The machine is equipped to produce uniform batch rolling, which is crucial for ensuring consistent product texture and appearance. Whether for hard candies, soft candies, or other confectionery products, the FLD-B Batch Roller ensures that the rolling process is even, contributing to uniformity in the final product.

Heat Preservation Function:

One of the standout features of the FLD-B Batch Roller is its heat preservation system, which helps maintain the desired temperature of the product during the rolling process. This ensures that the material does not cool too quickly, preventing issues such as crystallization, and enhancing the final texture of the candy.

Durable Construction:

Made from high-quality materials, the FLD-B Batch Roller is built to last. The machine is designed for continuous operation, providing long-term reliability with minimal maintenance. The robust build ensures that it can handle large-scale production while maintaining consistent performance over time.

User-Friendly Operation:

The FLD-B Batch Roller features an intuitive control panel, allowing for easy operation even for operators with minimal technical experience. This reduces the learning curve and enhances productivity by ensuring smooth transitions between operations.

Energy-Efficient:

Despite its high-speed performance, the FLD-B Batch Roller operates efficiently in terms of energy consumption. With a 2.7 kW motor, the machine offers excellent output without consuming excessive energy, contributing to lower operational costs.

Compact Design:

With compact dimensions of 2200 mm x 800 mm x 1150 mm, the FLD-B Batch Roller is designed to fit easily into most production lines. Its space-efficient design helps optimize the use of factory floor space, making it an ideal addition to any production facility with limited space.

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

Speed (revolution per minute)

|

|

FLD-B Batch roller

|

2.7

|

500

|

2200*800*1150

|

30-45

|

Advantages of the FLD-B Batch Roller:

Increased Production Efficiency:

The FLD-B Batch Roller boosts overall production efficiency by providing rapid, high-speed rolling without compromising the consistency or quality of the candy. With its adjustable speed, manufacturers can fine-tune the process to meet specific production requirements.

Improved Product Consistency:

The machine ensures uniform batch rolling, which is essential for producing consistently shaped candies with the same texture and quality in each batch. This consistency is vital for meeting consumer expectations and maintaining high product standards.

Energy and Cost Savings:

Thanks to its energy-efficient motor and high-speed operation, the FLD-B Batch Roller helps lower operational costs. It offers high output while consuming relatively low amounts of energy, making it an economically viable option for manufacturers looking to reduce expenses.

Versatile for Multiple Candy Types:

The FLD-B Batch Roller is adaptable for various types of confectionery products, including hard candies, soft candies, and other batch-based confections. Its versatile design makes it suitable for different stages of candy production, including rolling, cooling, and forming processes.

Easy to Maintain:

The FLD-B Batch Roller requires minimal maintenance due to its sturdy construction and simple design. Regular cleaning and periodic checks are sufficient to keep the machine running smoothly, reducing downtime and ensuring optimal performance over time.

Heat Preservation for Optimal Texture:

The heat preservation feature ensures that the candy mixture retains its ideal temperature during the rolling process. This is especially important for maintaining the texture and smoothness of the final product, preventing issues like sugar crystallization and ensuring a high-quality finished product.

The FLD-B Batch Roller by Flyloong is an advanced, high-performance machine that plays a crucial role in candy production. Whether you are producing hard candies, soft candies, or novelty confections, this machine guarantees high efficiency, consistent quality, and reliable operation. With its energy-efficient operation, heat preservation feature, and user-friendly design, the FLD-B Batch Roller is an ideal addition to any candy production line looking to enhance productivity and product consistency.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home