FLD-Mini Batch Roller – Compact and Efficient Candy Rolling Solution

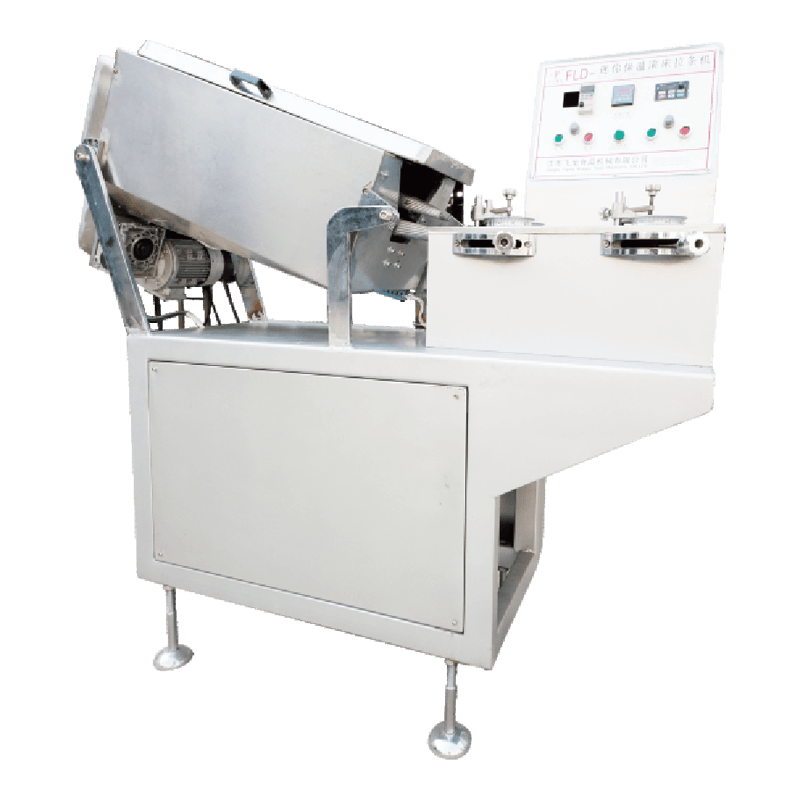

The FLD-Mini Connected Heat Insulation Rolling Machine, also known as the FLD-Mini Batch Roller, is a compact and high-efficiency machine designed for shaping sugar mass during the candy production process. Ideal for small to medium-scale confectionery operations, this machine combines precise heat retention with continuous rolling to deliver perfectly shaped sugar ropes for further processing.

As part of Flyloong Candy Machine Factory's precision-engineered product line, the FLD-Mini Batch Roller plays a critical role in the pre-forming stage of candy production. It works by continuously rolling heated sugar batches into uniform cylindrical shapes, which are then fed into forming or cutting machines. The integrated heat insulation system ensures that the sugar maintains its pliable texture, reducing cracking and improving consistency.

|

Machine Name

|

Power

|

Weight (kg)

|

Dimension (mm)

|

|

FLD- Mini Connected Heat Insulation Rolling Machine

|

1.8

|

220

|

1520*550*1320

|

Key Features

Compact and Space-Saving Design

With overall dimensions of 1520 × 550 × 1320 mm, this mini rolling machine is ideal for workshops or production lines with limited space, offering powerful performance in a compact footprint.

Efficient Power Output

Operating with a 1.8 kW motor, the machine delivers consistent and reliable rolling motion while maintaining energy efficiency, making it suitable for continuous production.

Heat Insulation System

Integrated heat-retaining elements help maintain the sugar mass at an optimal working temperature during the rolling process, ensuring uniform texture and preventing premature hardening.

Stable and Durable Construction

Weighing 220 kg, the machine is built with a sturdy frame that reduces vibration, enhances operational stability, and ensures long-term durability in demanding factory environments.

User-Friendly Operation

The simple control panel allows operators to manage rolling speed and temperature settings with ease, minimizing training requirements and improving productivity.

Applications

This mini batch roller is perfect for:

Shaping sugar masses before rope sizing or forming

Lollipop stick pre-rolling

Handcrafted candy production

Educational or demonstration candy setups

Small-batch artisan candy operations

It's especially valuable in production lines where precision, temperature control, and space efficiency are key.

Benefits of the FLD-Mini Batch Roller

Ensures uniform rolling of sugar masses

Maintains heat and texture consistency throughout processing

Easy to clean and maintain, with minimal downtime

Compatible with other Flyloong forming or cutting machines

Ideal for OEM customization based on different production requirements

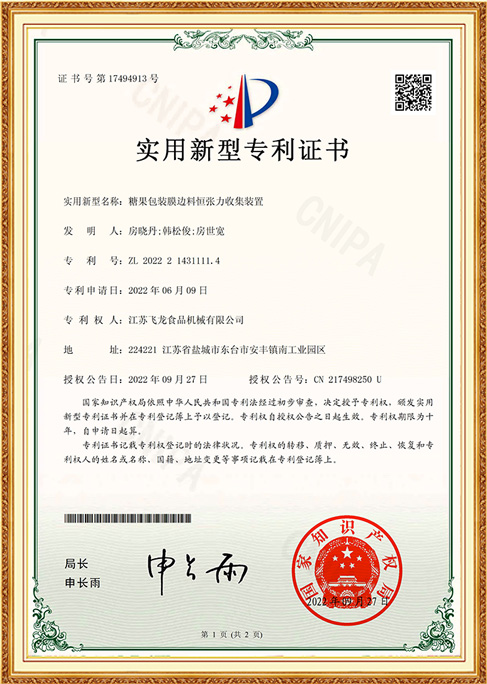

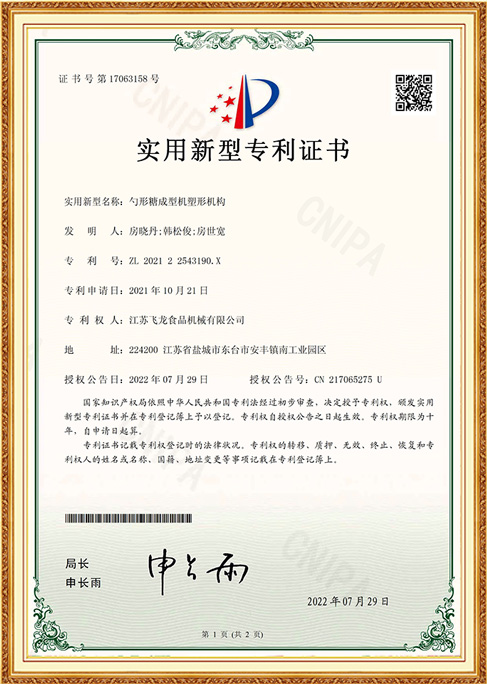

Flyloong specializes in manufacturing high-quality, user-focused candy machinery tailored to meet the specific needs of candy makers worldwide. The FLD-Mini Batch Roller reflects our commitment to performance, safety, and reliability in every detail.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home