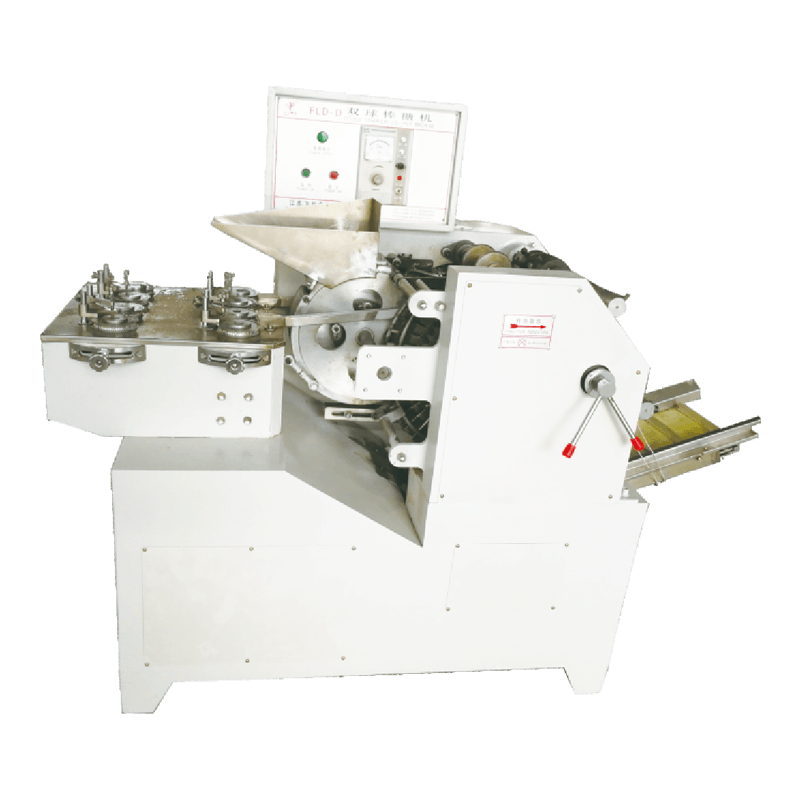

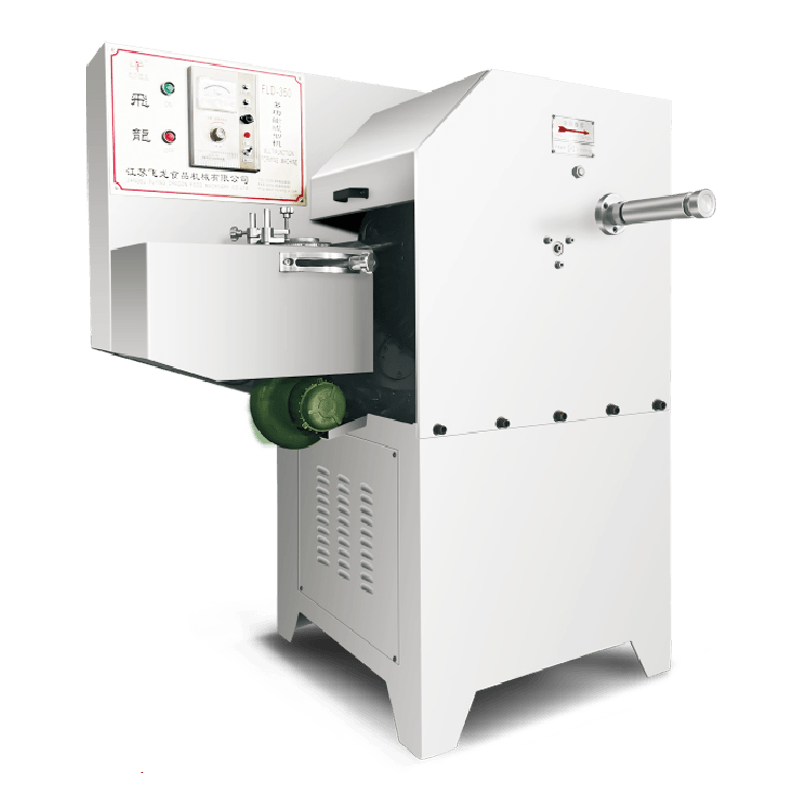

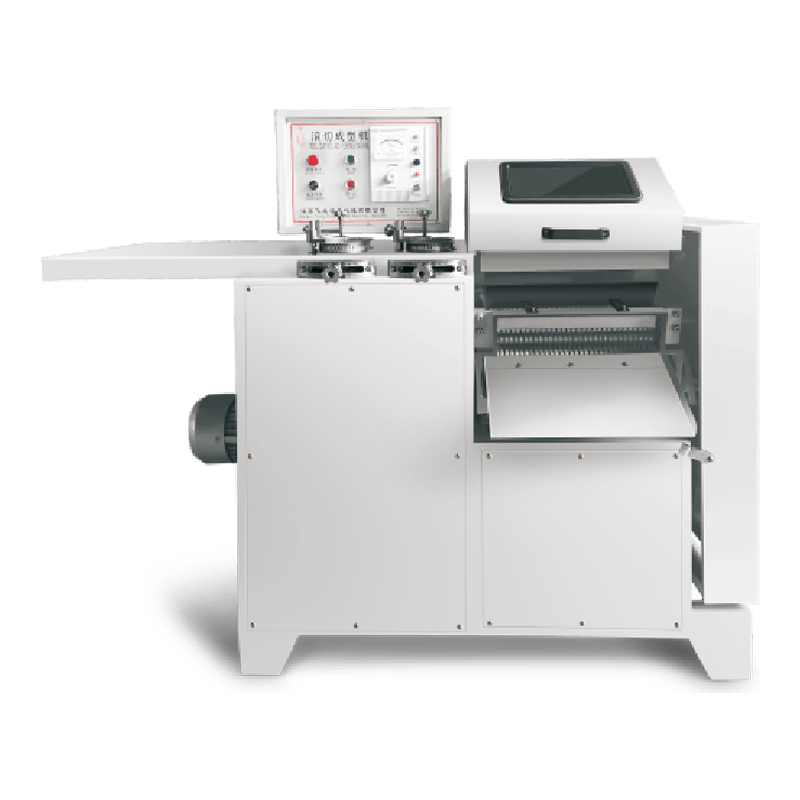

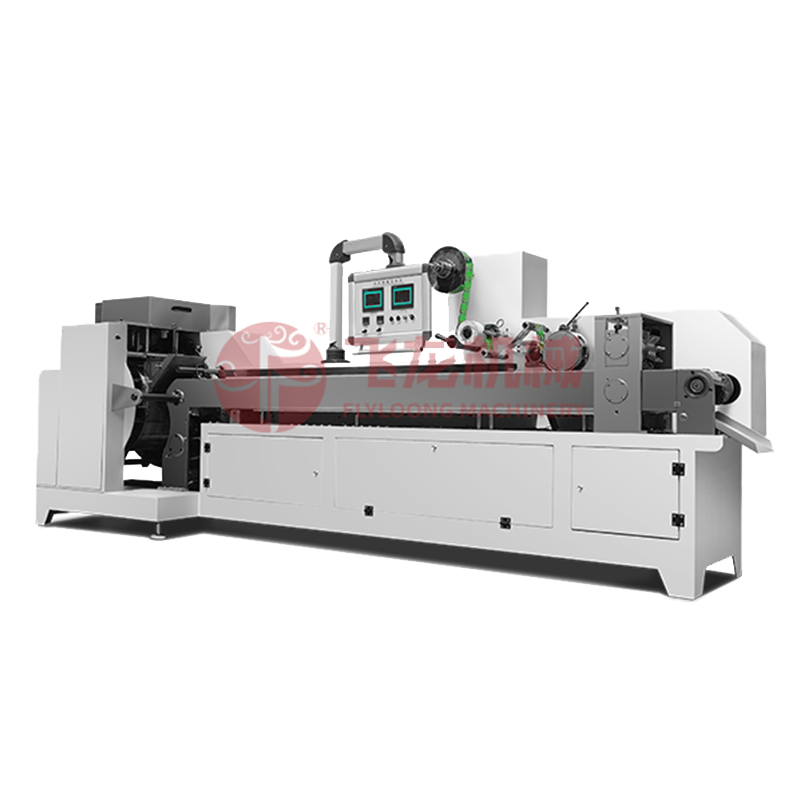

Candy Forming Machine: Precision Equipment for High-Quality Candy Production

In today's competitive confectionery market, manufacturers are under growing pressure to deliver candy that is not only delicious, but also uniform in shape, texture, and appearance. That's where the Candy Forming Machine becomes essential. Designed for high precision and consistent output, this machine is a key part of modern candy production lines. Whether you're producing hard candy, soft toffees, filled sweets, or novelty shapes, a reliable candy forming system ensures product quality, speed, and scalability.

A Candy Forming Machine is specialized equipment used to shape various types of confectionery by compressing, rolling, or molding candy mass into uniform pieces. It plays a critical role in automating the production process—reducing labor costs, increasing output, and enhancing consistency across batches.

Depending on the machine configuration and tooling system, it can produce:

Round, oval, or square hard candies

Chewy or filled toffees

Bubble gum tablets or balls

Flat or embossed candy logos

Multi-color or layered confections

Modern forming machines are often integrated into automated production lines, seamlessly connected with cooking, cooling, and packaging equipment.

The candy forming process typically includes the following steps:

Feeding: Candy mass is fed into the machine via batch roller or cooling belt.

Forming: The mass enters a forming unit, where rollers or die molds shape the candy using mechanical pressure.

Cutting: The shaped candy is cut into individual pieces with a synchronized cutting system.

Cooling and Conveying: The finished candies are transferred onto a cooling conveyor before packaging.

For filled candy, a center-filling system injects syrup, chocolate, or powder during the forming process.

Investing in a precision candy forming machine offers multiple long-term benefits for both startups and established manufacturers:

Scalability – Easily expand production as demand increases.

Product Quality – Ensure consistency and customer satisfaction.

Brand Differentiation – Create unique candy shapes that stand out on shelves.

Cost Efficiency – Reduce labor dependency and production waste.

Regulatory Compliance – Meet international food safety and packaging standards.

A Candy Forming Machine is more than just production equipment—it's a foundation for growth, innovation, and brand trust in the candy industry. With precision engineering, smart automation, and flexible operation, it enables candy producers to meet market demands while maintaining superior product quality.

Whether you're a startup aiming to scale or a large manufacturer expanding your product range, choosing the right forming machine is a critical step toward success.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home