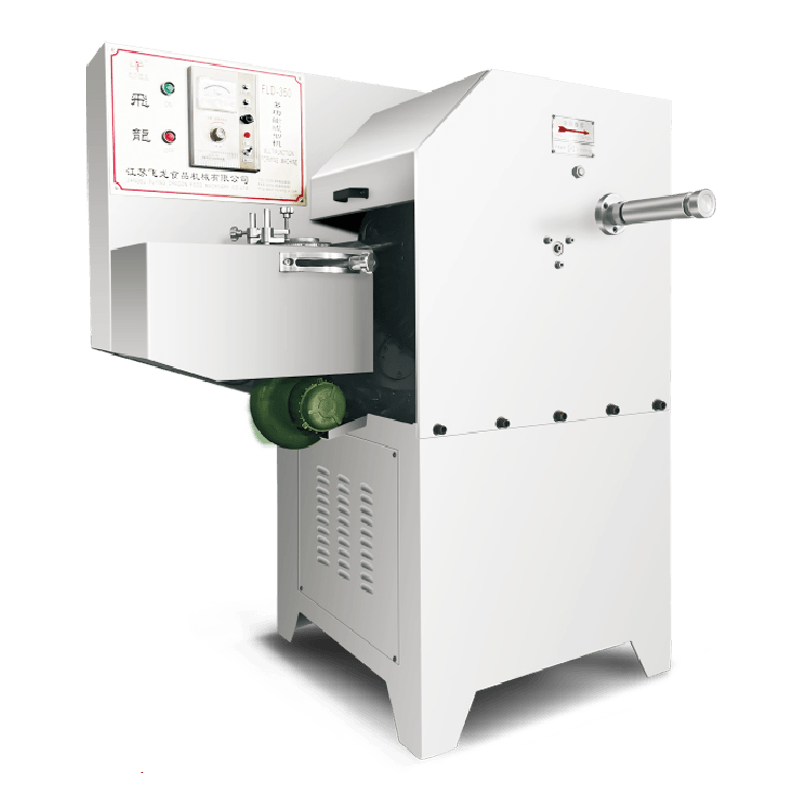

FLD-350 Hard Candy Machine

The FLD-350 is a proven, Hard Candy Machine designed for factories that require continuous operation with minimal stops. A single unit can produce solid hard candy, center-filled hard candy, soft milk candy, striped candy, and sandwich-style candy. Switch molds and adjust a few settings, and you can start the next product without extra machines.

Key Features of the FLD-350 Hard Candy Molding Machine

1. Versatile Candy Production

Handles almost every popular hard candy type on the market today:

solid pieces, jam/chocolate/gum-filled centers, soft milk candy, two-color stripes, and layered sandwich candy.

Flexible design allows rapid response to different customer orders and seasonal demands.

2. High Output Capacity

Suitable for medium to large production lines needing steady, high-volume output without quality loss during long shifts.

3. Precise Molding

Consistent weight, exact shape, and clean filling placement for every candy.

Low scrap rate, even during extended production runs.

4. Multi-function Capability

A true one-machine solution.

Capable of producing everything from basic hard candy to complex filled and layered products on the same line.

5. User-Friendly Operation

The FLD-350 features an easy-to-use control panel and a straightforward operating system.

Operators can quickly learn to use the machine and make adjustments with minimal downtime.

6. Durability and Reliability

Full food-grade stainless steel frame and components.

Designed for continuous 24-hour operation with very few breakdowns.

Daily cleaning is straightforward and meets all hygiene requirements.

8. Energy-Efficient Operation

Optimized motors and drives keep power consumption low while maintaining full production capacity.

Helps reduce electricity costs over time.

Applications

Hard Candy Production

Suitable for classic shapes such as balls, ovals, flat pieces, and 3D designs, as well as creative custom shapes.

Milk Candy Manufacturing

Produces smooth, creamy soft milk candy and toffee with consistent texture.

Sandwich Candies

Forms one candy shell around another candy or filling, ideal for premium double-layer products.

Novelty Candy Production

Custom molds for holiday themes, cartoon characters, promotional items, and special-event candies.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home