Key Features and Benefits:

Electromagnetic Heating: This cutting-edge technology allows for faster heating and precise temperature control, ensuring consistent quality and reduced energy consumption. It is ideal for sugar boiling in the confectionery industry.

Vacuum Cooking: The vacuum system effectively reduces the boiling temperature, preserving the natural qualities of the sugar and improving its transparency and texture. This method minimizes the risk of caramelization and discoloration, which is essential for producing high-quality syrup.

Automatic Discharging: The FLD-A machine is designed for convenience and efficiency. With automatic discharging, the syrup is processed continuously without the need for manual intervention, increasing productivity and reducing labor costs.

Improved Brightness and Transparency: The vacuum boiling process enhances the color and clarity of the syrup, ensuring the finished product meets industry standards for high-quality appearance.

Versatile Applications: Whether you're producing hard candy, caramel, or other sugar-based products, the FLD-A machine offers flexibility and reliability in continuous sugar syrup production.

High Efficiency: The rapid boiling process significantly reduces production time, allowing manufacturers to boost their output while maintaining the quality of the product.

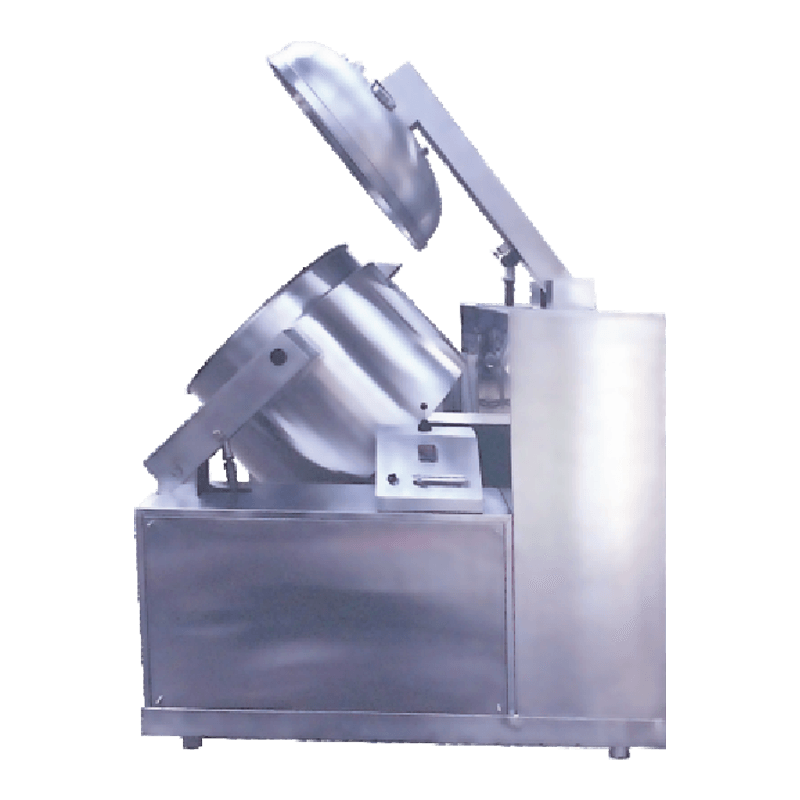

Compact and Robust Design: The machine's durable construction ensures long-lasting performance and easy integration into existing production lines.

Product Variants:

Fixed Laminated Pot: Ideal for mixing food raw materials in large batches.

Vacuum Sugar Cooking Pot: Perfect for continuous boiling sugar, particularly suited for hard candy production.

Small Vacuum Sugar Pot: Designed for small-scale users or low-volume operations, offering flexibility and efficient syrup boiling for smaller production runs.

Applications:

The FLD-A Electromagnetic Vacuum Sugar Boiling Machine is primarily used in the confectionery industry for the production of high-quality hard candies, caramels, and other sugar-based confections. Its ability to quickly and efficiently boil sugar syrup makes it indispensable for large-scale candy manufacturers. Additionally, it is highly suitable for industries requiring precise control over sugar syrup boiling, ensuring consistent product quality.

|

Machine Name

|

Power

|

Weight (kg)

|

Capacity

|

Capacity

|

|

FLD-A electromagnetic

vacuum sugar decanter

|

20

|

200

|

60

|

60 liters /20 minutes

|

|

FLD-B electromagnetic

vacuum sugar decanter

|

45

|

160

|

200

|

75 liters /22 minutes

|

|

FLD-C electromagnetic

vacuum sugar decanter

|

50

|

160

|

150

|

80 liters /35 minutes

|

|

FLD-D electromagnetic

vacuum sugar decanter

|

50

|

250

|

200

|

75 liters /22 minutes

|

|

FLD-E electromagnetic

vacuum sugar decanter

|

3

|

300

|

400

|

400 kg/hours

|

Parameters:

|

FLD.800

|

|

Capacity (L)

|

250

|

|

Weight

|

180

|

|

External dimensions

|

900×1100×1200

|

|

FLD.900

|

|

Capacity (L)

|

300

|

|

Weight

|

220

|

|

External dimensions

|

1000×1200×1300

|

|

FLD.1000

|

|

Capacity (L)

|

350

|

|

Weight

|

235

|

|

External dimensions

|

1100×1200 ×1400

|

|

Total power(kw)

|

3kw

|

|

Working pressure

|

0.59Mpa

|

|

Production capacity

|

400kg/h

|

|

3-4m/Pot

|

|

Vacuum

|

700~730mm.Hg

|

|

Steam consumption

|

110kg/h

|

|

Pot diameter

|

60mm

|

|

Sugar cooking quantity

|

120kg/h

|

|

Vacuum pump power

|

3kw

|

Why Choose the FLD-A Electromagnetic Vacuum Sugar Boiling Machine?

Faster Boiling Process: Save time and improve production efficiency with the electromagnetic heating system.

High-Quality Sugar Syrup: Achieve superior brightness, transparency, and texture for your sugar-based products.

Energy Efficient: Reduce operating costs with a machine that optimizes energy usage.

Fully Automatic: The automatic discharging system enhances productivity by reducing the need for manual labor.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home