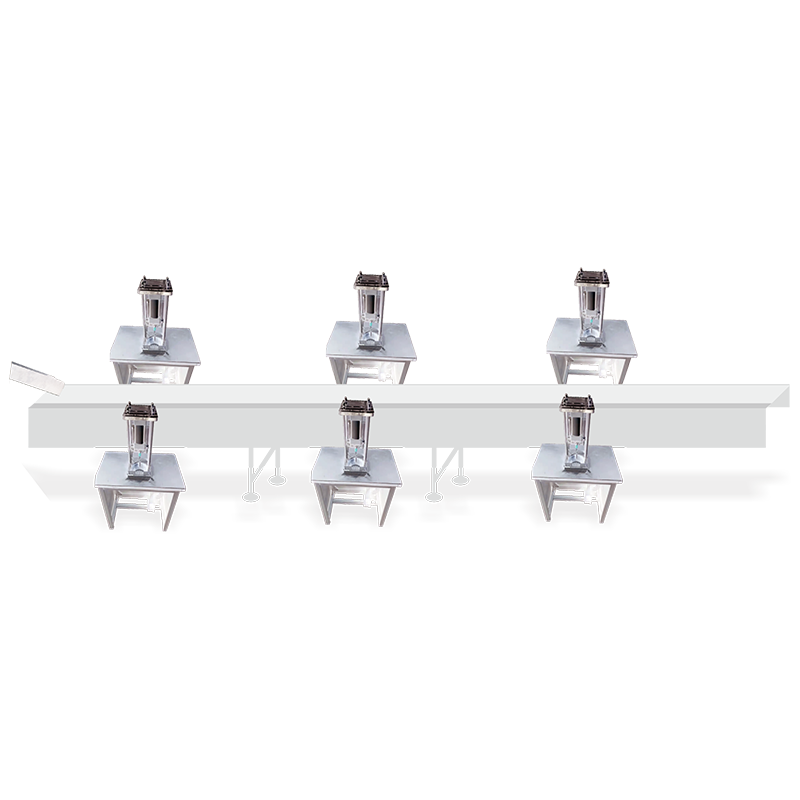

Key Features of the FLD-Feet Press Machine:

Precision Engineering:

The FLD-Feet Press Machine is built with a focus on precision, ensuring that every pressing operation is performed consistently and accurately. The machine provides uniform pressure, contributing to high-quality output with minimal error or variation.

Durable Construction:

This machine is designed for long-term durability, capable of withstanding continuous use in demanding production environments. Its robust construction ensures reliability, reducing the likelihood of breakdowns and maintenance needs, which in turn lowers operational costs over time.

Versatility:

One of the standout features of the FLD-Feet Press Machine is its versatility. It can be used across a wide range of industries, including manufacturing, textiles, and more. Whether you need to press materials for packaging, assembly, or shaping, this machine adapts to your production requirements.

Ease of Operation:

The FLD-Feet Press Machine is designed for ease of use. With user-friendly controls and an intuitive interface, operators can quickly get the machine up and running. Additionally, the machine requires minimal training, making it suitable for operations with limited technical expertise.

Energy Efficiency:

The machine operates efficiently, consuming minimal energy while still providing high output. This energy efficiency helps reduce operational costs, making it an economical choice for businesses looking to maximize their production capacity without significantly increasing their utility expenses.

Smooth Performance:

The machine operates smoothly, minimizing noise and vibrations during use. This is particularly advantageous for workplaces where a quieter operation is preferred, contributing to a more comfortable working environment for operators.

Maintenance-Friendly:

The FLD-Feet Press Machine is designed to be easy to maintain, with simple-to-follow guidelines for regular servicing and part replacements. Its straightforward design ensures that maintenance tasks can be carried out quickly, minimizing downtime and keeping production lines running smoothly.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

PDF Download

PDF Download

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home