Understanding the Basics of Lollipop Shaping

Producing differently shaped lollipops involves guiding molten candy into specially designed cavities or using mechanical pressure to force the candy into shape. Key factors include:

Mold Material & Construction

Metal (Aluminum, Stainless Steel): Fast cooling, highly durable, suited for high-volume operations.

Food-Grade Silicone: Flexible for easy demolding, used mainly in small-scale or artisanal setups.

Plastic (Polycarbonate): Offers transparency (to see fill level), but slower cooling and less durable.

Draft Angle & Release Mechanism

All molds require a slight taper (1–3°) on vertical walls (“draft”) so the hardened lollipop can be removed without tearing or sticking.

Complex shapes (e.g., figurines with undercuts) often need multi-part molds or side cores that retract before ejection.

Viscosity & Temperature Control

Molten sugar (around 148 °C/300 °F) must remain fluid long enough to fill every nook. If the mold is too cold, the candy starts to set before the cavity is full, resulting in voids.

Some recipes add glucose or corn syrup to lower crystallization risk, ensuring a consistent fill in detailed molds.

2. Primary Shaping Methods

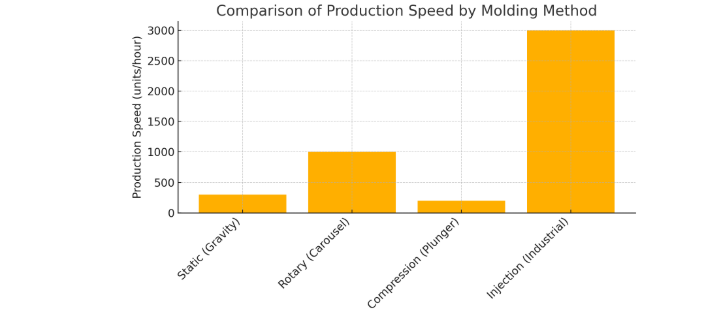

Four main approaches are used in the industry. Each varies in complexity, cycle time, and level of detail achievable:

2.1 Static (Gravity-Fill) Molding

Process Steps:

Heat & Liquefy: Sugar (with color and flavor) is cooked to ~148 °C.

Dispense into Stationary Molds: Molten candy is poured (via gravity or low-pressure pump) into fixed mold plates on a flat conveyor or table. A stick is pre-placed in a small indentation.

Cool & Harden: Molds pass under or through a cooling zone (fan or cold air tunnel).

Demold: Once sufficiently hardened (usually 15–30 seconds), the plate opens, and a simple ejector pushes the pop onto a collection belt.

Shape Capability:

Moderately Detailed: Hearts, stars, simple characters, or flat logos work well.

Limitations: Undercuts (deep recesses) are difficult; cavities must be tapered.

Advantages & Limitations:

| Aspect | Details |

|---|---|

| Ease of Setup | (Simple plates; swap molds in <2 minutes) |

| Production Speed | ~300 units/hour per station (varies with mold count and cooling efficiency) |

| Detail Level | (No undercuts; basic reliefs and shapes only) |

| Ideal Run Size | Up to ~10 000/week |

| Maintenance |

Low (minimal moving parts; occasional cleaning of sugar residue) |

Rotary (Carousel) Molding

Process Steps:

Carousel Setup: Multiple mold pockets are mounted on a rotating plate.

Dispense: At a designated fill station, a precise nozzle injects molten candy into each pocket. A stick-holding pin (or clip) keeps the stick centered.

Immediate Cooling: After filling, pockets rotate under chilled plates or air-blast nozzles to start rapid solidification.

Eject: About 30–60 seconds later, the pocket aligns with an ejector mechanism. A pin pushes out the finished lollipop, which falls onto a mini conveyor or sweep arm.

Shape Capability:

Highly Detailed: Intricate reliefs, undercuts, multi-part shapes (e.g., cartoon faces, logos).

Multi-Color/Layer: Can use sequential nozzles for layering (e.g., inject red base, then white top).

Advantages & Limitations:

| Aspect | Details |

|---|---|

| Ease of Setup | (Plate alignment and timing adjustments take ~5–10 minutes) |

| Production Speed | ~1 000 units/hour (depending on number of cavities and cycle length) |

| Detail Level | (Supports undercuts, side cores, multi-layer fills) |

| Ideal Run Size | ~10 000–50 000/week |

| Maintenance | Moderate (precision cams and nozzles need periodic calibration/cleaning) |

Compression (Plunger) Molding

Process Steps:

Pour or Place Candy Pre-Slug: A measured “slug” of warm sugar (slightly below 148 °C) is dropped into a bottom mold cavity.

Compress: A matching top plunger descends, forcing candy to fill the entire cavity. Excess candy is squeezed out along the edges.

Cooling: Compressed candy remains in contact with chilled mold surfaces for ~10–20 seconds.

Eject: Ejector pins in the bottom plate push the shaped pop onto a discharge belt.

Shape Capability:

Best for Flat or Thin Shapes: Logos, medals, thin reliefs (e.g., corporate insignias or shallow designs).

Limited 3D Depth: Deep or rounded shapes are harder to replicate with a simple plunger.

Advantages & Limitations:

| Aspect | Details |

|---|---|

| Ease of Setup | (Plunger alignment requires precision; cavity wear impacts fit) |

| Production Speed | ~200 units/hour (cycle involves compression + cooling) |

| Detail Level | (Excellent for crisp, shallow relief but not deep undercuts) |

| Ideal Run Size | Up to ~10 000/week |

| Maintenance | Moderate (plunger seals and mold surfaces need periodic inspection) |

Injection Molding (High-Capacity/Industrial)

Process Steps:

Heated Feed & Manifold: Molten candy is held in a heated manifold (to prevent premature crystallization).

High-Pressure Injection: Hydraulic or ram-style actuators push candy through “hot runner” nozzles into each cavity simultaneously.

Rapid Cooling: Mold cavities are surrounded by coolant channels (water or glycol) to quickly solidify the candy.

Eject & Trim: After a precise fill and dwell time (~5–15 seconds), hydraulic ejector plates push the pops out; an automated scraper or belt removes any flash.

Shape Capability:

Extremely Detailed: Can handle undercuts, multi-slide mold actions, side cores.

Multi-Color/Layer Options: Different sugar streams can be injected sequentially or co-injected.

Advantages & Limitations:

| Aspect | Details |

|---|---|

| Ease of Setup | (Complex manifold alignment and parameter tuning; mold changes require hours) |

| Production Speed | ~3 000 units/hour (varies with cavity count; industrial multi-cavity molds can push even higher) |

| Detail Level | (Top-tier precision; ideal for branding, multi-layer graphics) |

| Ideal Run Size | > 50 000/week |

| Maintenance | High (hydraulic systems, hot runners, and precision valves need constant upkeep) |

Stay tuned for our upcoming article.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home