What is a Flat Lollipop Golden Wire Twist Packing Machine?

A Flat Lollipop Golden Wire Twist Packing Machine is a highly automated packaging system specifically designed to pack flat lollipops. It wraps each lollipop with a high-quality wrapper, using a unique golden wire twist mechanism to seal the package. This packaging system is optimized for high-volume production, ensuring that each lollipop is individually wrapped in a manner that maintains both its freshness and its visual appeal.

The primary function of the machine is to take a flat lollipop, place it into a packaging material, and then twist and seal the wrapper at both ends, forming a secure, airtight seal. The machine operates with precision, wrapping each lollipop uniformly, thus ensuring consistent packaging standards across large batches. It’s widely used in both small-scale and mass-production candy manufacturing lines, offering the dual benefits of speed and consistency.

Basic Functionality:

Film Wrapping: The machine feeds a specific film material, usually a plastic wrap, which is used to enclose each lollipop.

Twisting and Securing: Once the lollipop is inserted, the machine automatically twists the ends of the wrapper and secures it with a decorative golden wire, ensuring the candy remains in place.

Sealing: After the wrapping is complete, the machine seals the ends of the film to prevent any leakage or contamination, keeping the lollipop safe and fresh.

Key Components and Their Roles in the Packaging Process

Film Roll: The machine uses a roll of packaging film, which is unwound and used to wrap each lollipop. The type of film can vary depending on the desired appearance and product protection needs.

Feeding Mechanism: This component ensures a steady supply of lollipops into the machine. The feeding system is designed to handle lollipops with varying sizes and shapes while maintaining precise positioning.

Wrapping Unit: The wrapping unit forms the core function of the machine, wrapping the film around the lollipop. The machine ensures that the wrapper is tightly sealed, preventing any air or moisture from entering.

Twisting Mechanism: After wrapping, the twisting mechanism twists both ends of the film tightly and secures them using a golden wire, which adds to the product's visual appeal.

Cutting Tool: This tool ensures the wrapping film is cut neatly after the twist, ensuring each lollipop is individually wrapped and ready for packaging.

Control Panel: The control panel allows operators to set the machine's parameters, such as wrapping speed, tension of the film, and twist tightness, ensuring customization for different production runs.

Key Features of the Flat Lollipop Golden Wire Twist Packing Machine

The Flat Lollipop Golden Wire Twist Packing Machine is designed with innovative features that ensure efficient, secure, and aesthetically pleasing packaging. Below are some of the standout features of this machine:

Advanced Wrapping Technology:

The machine uses cutting-edge wrapping technology to ensure each lollipop is wrapped tightly and securely in a flat film. This method provides consistent coverage and prevents air or moisture from entering, which can impact the quality of the product.

Golden Wire Twist Closure:

One of the machine's signature features is its ability to secure the lollipop packaging with a golden wire twist. This addition not only enhances the product's visual appeal but also acts as an extra measure of security to prevent the wrapper from unraveling during handling and transportation.

Adjustable Speed and Tension Control:

The machine comes with user-friendly controls that allow for adjustments in speed and film tension. This feature ensures flexibility, enabling the machine to handle different production volumes and adapt to various film types and thicknesses.

Durable and Reliable Construction:

Built with high-quality materials, the Flat Lollipop Golden Wire Twist Packing Machine is designed to withstand continuous, high-speed operation. Its robust construction ensures minimal downtime, even during long production runs, making it ideal for large-scale manufacturing.

Precision Cutting System:

The machine features a precision cutting system that neatly trims the wrapping film after the twist, ensuring that each lollipop is individually packaged to perfection. This feature helps maintain uniformity in the appearance of each finished product, providing a professional, high-quality look.

Automatic and Continuous Operation:

The machine operates automatically, from film feeding to lollipop wrapping, twisting, and sealing. This continuous operation reduces the need for manual intervention, leading to higher efficiency and lower labor costs. The automation process also ensures consistency across the production line, reducing the chances of human error.

Easy Maintenance and Cleaning:

Maintenance of the machine is straightforward, thanks to its modular design and easy-to-access components. Regular cleaning and upkeep are simplified, ensuring that the machine remains in optimal condition and continues to function effectively throughout its lifecycle.

Versatility for Different Product Sizes:

This machine is adaptable to various sizes of lollipops, making it suitable for manufacturers producing multiple types of candy. The ability to switch between different lollipop sizes without requiring significant adjustments makes this machine highly versatile.

Key Features of the Flat Lollipop Golden Wire Twist Packing Machine

| Feature | Description |

|---|---|

| Advanced Wrapping Technology | Uses cutting-edge wrapping technology for tight and secure packaging, ensuring no air or moisture enters. |

| Golden Wire Twist Closure | Secures the lollipop with a golden wire twist, adding visual appeal and preventing wrapper unravelling. |

| Adjustable Speed and Tension Control | Provides flexibility in adjusting wrapping speed and film tension to handle various film types and production volumes. |

| Durable and Reliable Construction | Built with high-quality materials to withstand continuous, high-speed operation, ensuring minimal downtime. |

| Precision Cutting System | Features a precision cutting system to neatly trim the wrapping film after twisting, providing uniformity in packaging. |

| Automatic and Continuous Operation | Fully automated operation from feeding to wrapping, twisting, and sealing, reducing labor costs and ensuring high consistency. |

| Easy Maintenance and Cleaning | Simple maintenance due to modular design and easy-to-access components, ensuring optimal functionality. |

| Versatility for Different Product Sizes | Adaptable to various lollipop sizes, making the machine suitable for different types of candy without major adjustments. |

Advantages of Using Flat Lollipop Golden Wire Twist Packing Machines

Adopting the Flat Lollipop Golden Wire Twist Packing Machine offers several advantages for manufacturers in the confectionery industry. Here are the key benefits:

Increased Production Efficiency:

The automated process significantly speeds up the packaging operation, allowing manufacturers to handle a larger volume of lollipops without compromising quality. This efficiency leads to faster turnaround times and a higher production capacity, benefiting businesses with high demand.

Improved Product Appeal:

The golden wire twist and flat packaging design give each lollipop a premium, high-end look that enhances its appeal on store shelves. Consumers are often drawn to visually striking products, and this unique packaging helps differentiate your brand from competitors.

Cost-Effective Packaging Solution:

By automating the packing process, this machine reduces the need for manual labor, resulting in lower labor costs. Additionally, the machine minimizes material waste by precisely cutting and wrapping each lollipop. These cost savings can be significant over time, especially for businesses with high production volumes.

Consistency and Quality Control:

Automation ensures that each lollipop is wrapped and twisted in exactly the same way, leading to consistent quality. This uniformity is crucial for businesses aiming to maintain brand reputation and customer satisfaction, as consumers expect the same high-quality packaging with every purchase.

Reduced Risk of Contamination:

With the tightly wrapped packaging and the use of high-quality film, the risk of contamination from external elements is minimized. The machine ensures that each lollipop is securely sealed, helping to extend shelf life and maintain the candy's freshness and hygiene.

Space Optimization:

The flat packaging style not only creates a visually appealing product but also optimizes space, allowing more lollipops to be packed into cartons. This leads to reduced storage space requirements and more efficient shipping, which can lower logistical costs.

Customization Options:

The machine offers flexibility in terms of film materials and design, allowing manufacturers to customize the packaging according to brand needs. Whether you're looking to incorporate branding, seasonal designs, or promotional features, the machine can accommodate various film options and graphics.

Reduced Downtime:

With minimal manual intervention needed, the Flat Lollipop Golden Wire Twist Packing Machine runs smoothly for longer periods, reducing downtime and increasing overall productivity. The machine's design also ensures easy troubleshooting and maintenance, further limiting disruptions to production.

Environmentally Friendly Options:

Some versions of the machine are compatible with biodegradable or recyclable films, offering manufacturers an opportunity to promote sustainable practices. By adopting eco-friendly materials, businesses can reduce their environmental footprint while still achieving high-quality packaging.

Advantages of Using the Flat Lollipop Golden Wire Twist Packing Machine

| Advantage | Description |

|---|---|

| Increased Production Efficiency | Speeds up the packaging process, increasing production volume while maintaining high quality, benefiting businesses with high demand. |

| Improved Product Appeal | Provides a premium, high-end look with golden wire twist and flat packaging, enhancing shelf appeal and consumer attraction. |

| Cost-Effective Packaging Solution | Reduces labor costs and material waste, offering significant cost savings over time, especially with large production volumes. |

| Consistency and Quality Control | Ensures uniformity in packaging, maintaining high standards of quality and enhancing brand reputation through consistent product presentation. |

| Reduced Risk of Contamination | Secures the lollipop with tight, high-quality film wrapping, reducing the chance of contamination and extending the product's shelf life. |

| Space Optimization | Flat packaging design allows for better space utilization, leading to reduced storage and shipping costs due to more efficient packing. |

| Customization Options | Flexible design options for film materials and branding, allowing manufacturers to customize packaging for marketing needs or seasonal promotions. |

| Reduced Downtime | Minimal manual intervention and easy troubleshooting reduces machine downtime, maximizing productivity. |

| Environmentally Friendly Options | Some machines support biodegradable or recyclable films, offering an eco-friendly alternative and reducing the environmental footprint. |

Types and Their Applications of Flat Lollipop Golden Wire Twist Packing Machines

The Flat Lollipop Golden Wire Twist Packing Machine is an essential tool for the modern confectionery industry. These machines come in various types, each tailored to different production requirements, production volumes, and product types. Whether for small artisanal businesses or large-scale manufacturers, the variety of machines ensures there's a suitable option for every packaging need.

Types of Flat Lollipop Golden Wire Twist Packing Machines

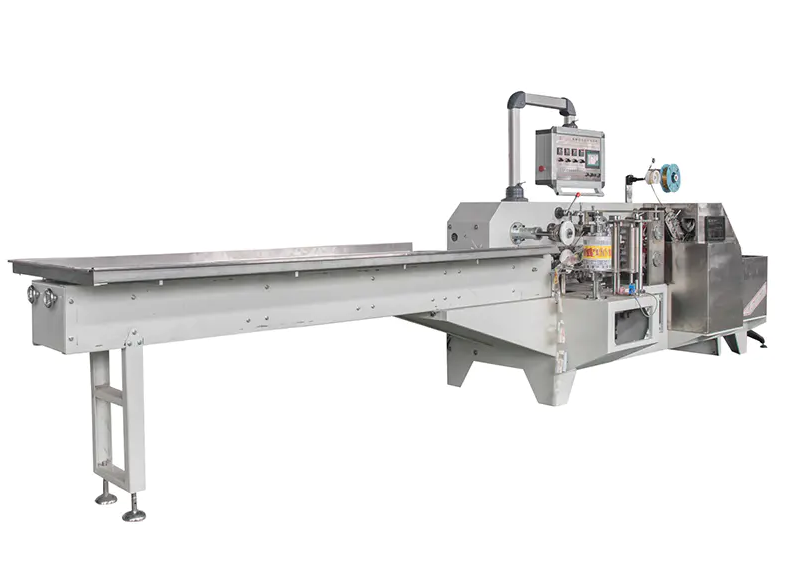

Semi-Automatic Flat Lollipop Packing Machine

The semi-automatic version of the Flat Lollipop Golden Wire Twist Packing Machine combines both manual and automatic functions. Operators manually load the lollipops onto the machine, which then automates the wrapping, twisting, and sealing processes. This type is perfect for small to medium production volumes and offers flexibility for businesses with a varied product range.

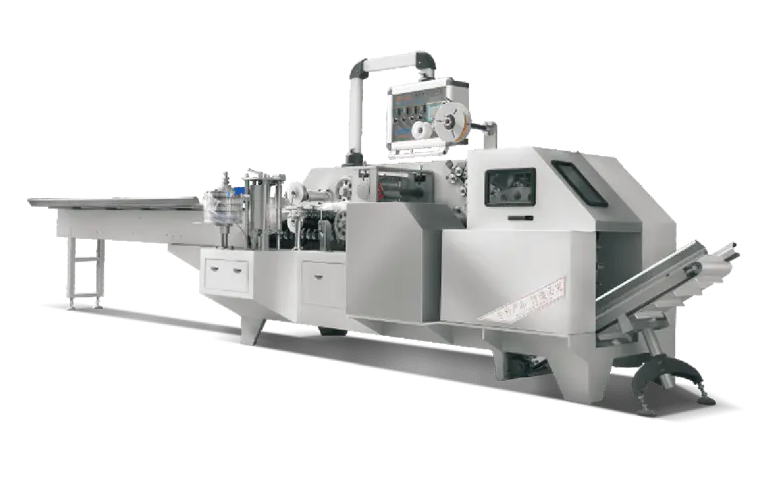

Fully Automatic Flat Lollipop Packing Machine

As the name suggests, this machine handles the entire process automatically, from feeding the lollipops into the machine to wrapping, twisting, and sealing the packaging. The fully automatic machine is ideal for large-scale confectionery manufacturers who need to increase production efficiency and reduce labor costs. It is designed to operate continuously, making it suitable for high-volume production environments.

High-Speed Flat Lollipop Packing Machine

For manufacturers with high demand, the high-speed flat lollipop packing machine offers enhanced speed and efficiency. This machine is built to handle large volumes of lollipops in a short amount of time, significantly boosting productivity while maintaining packaging quality. It is perfect for businesses that need to meet strict production deadlines or have a large distribution network.

Compact Flat Lollipop Packing Machine

The compact version of the flat lollipop packing machine is designed for businesses with limited space or for smaller production runs. Despite its smaller size, this machine does not compromise on efficiency and ensures precise wrapping and twisting. It's an excellent option for small-scale manufacturers or those with limited factory floor space.

Multi-Function Flat Lollipop Packing Machine

This versatile machine can handle multiple types of packaging, not just lollipops. It is designed for manufacturers who wish to use the same machine for various confectionery products with similar packaging requirements. With this machine, businesses can achieve greater flexibility in their production line, reducing the need for separate packaging machines for different products.

Eco-Friendly Flat Lollipop Packing Machine

The eco-friendly version of the flat lollipop packing machine is built to accommodate biodegradable or recyclable films. This type of machine is particularly popular among manufacturers looking to align with sustainability initiatives and reduce their environmental footprint. By using eco-friendly packaging materials, businesses can cater to environmentally conscious consumers.

Types of Flat Lollipop Golden Wire Twist Packing Machines

| Type | Description |

|---|---|

| Semi-Automatic Flat Lollipop Packing Machine | Requires manual intervention for loading, but automates the wrapping, twisting, and sealing processes. Ideal for small to medium production volumes. |

| Fully Automatic Flat Lollipop Packing Machine | Fully automated, handles the entire process, best for high-volume production with continuous operation. |

| High-Speed Flat Lollipop Packing Machine | Designed for high-speed operation, this machine handles large volumes quickly, making it suitable for businesses with high production demands. |

| Compact Flat Lollipop Packing Machine | A smaller, space-saving machine suitable for businesses with limited space or lower production volumes. |

| Multi-Function Flat Lollipop Packing Machine | Can be used for various confectionery products with similar packaging needs, offering more versatility on the production line. |

| Eco-Friendly Flat Lollipop Packing Machine | Accommodates biodegradable or recyclable films, suitable for businesses focused on sustainability and reducing environmental impact. |

Applications of Flat Lollipop Golden Wire Twist Packing Machines

Confectionery Manufacturing

The most common application of the flat lollipop golden wire twist packing machine is in the mass production of lollipops. These machines automate the entire wrapping and sealing process, making them ideal for large-scale confectionery production.

Premium Candy Brands

High-end candy brands often prefer the golden wire twist packing machine because it gives their lollipops an elegant, premium appearance. The twist closure and flat packaging make the product visually appealing and stand out in retail stores, which is crucial for attracting consumers.

Seasonal and Themed Packaging

Manufacturers producing limited-edition or seasonal lollipops, such as holiday-themed candies, use these machines to create custom packaging. The machine's ability to use different colored wires and wrappers allows for easy customization to fit the theme of the season or promotion.

Eco-Friendly Product Lines

The eco-friendly version of the machine is a growing trend in the industry, as more businesses move towards sustainable packaging solutions. These machines allow manufacturers to use biodegradable or recyclable films, making them a great choice for companies seeking to reduce waste and offer environmentally conscious products.

Gift and Party Favor Packaging

The attractive flat twist packaging is also used for gift items and party favors. For special occasions or corporate gifts, the lollipops are packaged in a way that highlights their premium quality, making them a popular choice for manufacturers of gift items.

Bulk Packaging for Retail

High-volume fully automatic machines are often used by manufacturers that need to package large quantities of lollipops for retail distribution. These machines can handle mass production efficiently and deliver consistently packaged products that are ready for shipping.

Small-Scale Confectionery Production

For smaller confectionery businesses, a semi-automatic machine provides a great balance of manual input and automation. These machines allow for flexibility in production without requiring the same investment as high-capacity machines, making them ideal for smaller producers or boutique confectionery brands.

International Distribution

In international markets, manufacturers use flat lollipop packing machines to prepare products for shipping across long distances. The tight and secure packaging ensures that the lollipops remain fresh and intact during transportation, preventing breakage or contamination.

Applications of Flat Lollipop Golden Wire Twist Packing Machines

| Application | Description |

|---|---|

| Confectionery Manufacturing | Used for the mass production of lollipops, automating the wrapping process to meet high-volume demands. |

| Premium Candy Brands | Used for high-end lollipops, enhancing visual appeal with golden wire twist packaging. |

| Seasonal and Themed Packaging | Ideal for creating seasonal or themed packaging for limited edition lollipops, perfect for holiday promotions. |

| Eco-Friendly Product Lines | Used with biodegradable or recyclable films for manufacturers aiming to align with sustainable packaging practices. |

| Gift and Party Favor Packaging | Popular for packaging lollipops as premium gift items or party favors, where presentation is key. |

| Bulk Packaging for Retail | Suited for large-scale retail packaging, allowing for efficient, high-volume production and consistent packaging quality. |

| Small-Scale Confectionery Production | Perfect for smaller manufacturers or boutique confectioners who require flexible, semi-automatic packaging. |

| International Distribution | Ensures lollipops are securely wrapped and protected for long-distance shipping, preventing damage during transit. |

How the Flat Lollipop Golden Wire Twist Packing Machine Differs from Other Lollipop Packaging Machines

1. Unique Flat Packaging Design

One of the most distinctive features of the Flat Lollipop Golden Wire Twist Packing Machine is its ability to wrap lollipops in a flat packaging design. Unlike traditional lollipop packaging machines that often create a rounded or cylindrical wrapper, this machine wraps the lollipop in a sleek, flat package. The flat wrapping not only improves the overall aesthetics of the lollipop but also optimizes space, allowing for more efficient storage and shipping. This space-saving design is especially beneficial for retail display purposes, where products need to be arranged in a visually appealing way.

Key Difference: Traditional machines usually create rounded packaging, while the flat packaging is more streamlined and provides better space utilization.

2. Golden Wire Twist Closure

The golden wire twist used to seal the packaging is another feature that differentiates this machine from others. Traditional packaging machines often rely on simple plastic ties or heat-sealing methods to close the wrapper, but the golden wire twist offers a decorative, elegant, and premium touch. This golden twist closure not only ensures the package is tightly sealed but also enhances the product's visual appeal. It gives the lollipop a high-end, festive look that can attract consumers, especially in the premium candy market.

Key Difference: Most other machines use basic sealing or plastic ties, while the golden wire twist adds a luxurious and decorative touch to the packaging.

3. Automation and Speed

The Flat Lollipop Golden Wire Twist Packing Machine is designed to be highly automated, offering continuous, high-speed operation. In comparison, other lollipop packaging machines might require more manual intervention or have slower processing speeds. For example, semi-automatic machines require operators to load the lollipops manually, which can slow down the production process. In contrast, the fully automatic version of this machine automates the entire process, from film feeding to twisting and sealing, allowing for faster production cycles.

Key Difference: The fully automated operation and higher speed make the flat lollipop packing machine more efficient than machines that require manual intervention or slower automation processes.

4. Customization and Flexibility

Another key difference lies in the level of customization available with the Flat Lollipop Golden Wire Twist Packing Machine. The machine can be easily adapted to various lollipop sizes and packaging requirements, offering manufacturers the flexibility to change packaging designs based on seasonal or promotional needs. This level of customization is often not available with other lollipop packaging machines, which are typically designed to handle only specific lollipop sizes or types of wrappers.

Key Difference: The flat lollipop packing machine offers more flexibility and customization for packaging different sizes and types of lollipops compared to other machines that may be limited in their adaptability.

5. Aesthetic Appeal and Premium Branding

The combination of the flat packaging and golden wire twist closure gives the Flat Lollipop Golden Wire Twist Packing Machine a strong advantage in terms of branding and marketing. Packaging plays a crucial role in the perception of the product, especially in the candy industry. While other machines may create functional but plain packaging, this machine allows manufacturers to create a product that looks as good as it tastes. The golden wire twist offers a premium look, making it ideal for candy brands that want to create a luxury or special-edition product.

Key Difference: Other machines may focus more on functionality than aesthetics, but the flat lollipop golden wire twist packing machine excels in premium branding and luxury appeal.

6. Packaging Security

When compared to traditional lollipop packaging machines, the Flat Lollipop Golden Wire Twist Packing Machine offers a more secure packaging solution. The golden wire twist not only provides a strong closure but also helps prevent accidental unwrapping. In contrast, other machines may rely on simple heat sealing or plastic wrappers that can be prone to breaking or slipping off, particularly when the product is handled during transportation or distribution. The flat twist design ensures that the packaging remains intact even in transit, which reduces product loss and increases consumer satisfaction.

Key Difference: The golden wire twist closure provides superior security and protection, unlike other methods that may not ensure the same level of product integrity.

7. Space Efficiency and Storage

As mentioned earlier, the flat packaging design provides significant space-saving advantages. This feature is particularly beneficial for manufacturers who need to store large quantities of lollipops in compact spaces or for retailers looking to maximize shelf space. Traditional machines, which create more rounded or bulky packaging, can take up more space both during production and in storage. The flat lollipop golden wire twist packing machine maximizes space utilization, making it an ideal choice for businesses that need to optimize storage and transportation.

Key Difference: The flat design allows for more efficient space utilization compared to traditional packaging designs that can be bulkier and less space-efficient.

8. Environmental Considerations

With an increasing focus on sustainability, some versions of the Flat Lollipop Golden Wire Twist Packing Machine offer compatibility with biodegradable or recyclable films. While other lollipop packaging machines may primarily use plastic materials that contribute to environmental waste, this machine offers manufacturers the ability to choose more eco-friendly options, aligning with consumer demand for greener products.

Key Difference: The ability to use sustainable packaging materials is an added feature of the flat lollipop packing machine, which is often not available with other traditional machines.

How the Flat Lollipop Golden Wire Twist Packing Machine Differs from Other Lollipop Packaging Machines

| Feature | Flat Lollipop Golden Wire Twist Packing Machine | Other Lollipop Packaging Machines |

|---|---|---|

| Packaging Design | Flat packaging design, sleek and space-efficient. | Traditional rounded or cylindrical packaging. |

| Closure Type | Golden wire twist for premium look and secure sealing. | Basic plastic ties or heat sealing methods. |

| Automation | Fully automated with high-speed operation, reducing manual labor. | Some machines are semi-automatic or slower in operation. |

| Customization | Highly customizable for different lollipop sizes and packaging designs. | Often limited to specific sizes or packaging types. |

| Branding and Aesthetic Appeal | Premium, luxurious appeal with golden wire twist. | Focus on functionality, often without emphasis on aesthetics. |

| Packaging Security | Strong, secure twist closure ensures the packaging stays intact. | Seals may not provide the same level of security, prone to slipping or breaking. |

| Space Efficiency | Optimized flat design allows for better space utilization in storage and display. | Bulky, rounded packaging takes up more space. |

| Environmental Impact | Option for eco-friendly, biodegradable or recyclable films. | Primarily uses plastic materials, contributing to environmental waste. |

How the Flat Lollipop Golden Wire Twist Packing Machine Works

This machine is engineered for efficiency, precision, and visual appeal, ensuring that each lollipop is individually wrapped in a secure, aesthetically pleasing package.

1. Loading and Feeding of Lollipops

The first step in the packaging process is the loading and feeding of the lollipops into the machine. In most models, this is either done manually (in semi-automatic machines) or automatically (in fully automated machines). The lollipops are carefully placed into the feeder, which then directs them towards the wrapping station.

Manual Loading: In semi-automatic versions, operators place the lollipops into the machine's feeding system.

Automatic Loading: Fully automated machines use conveyor belts or robotic arms to transport lollipops into position without human intervention.

This step ensures that the lollipops are aligned correctly and prepared for the next stages of packaging.

2. Wrapping the Lollipop

Once the lollipop is properly positioned, the wrapping unit takes over. The machine uses a roll of packaging film, typically made of plastic, that is fed into the machine. The film is precisely measured and cut to the appropriate size, ensuring a snug fit around the lollipop.

Film Feeding: The packaging film is unwound from the roll and guided toward the lollipop.

Wrapping Process: The machine wraps the film tightly around the lollipop, making sure it is covered completely, leaving no gaps. This step is critical to maintain hygiene and freshness during storage and distribution.

The flat packaging design is formed during this step, setting it apart from other machines that create more rounded or bulky wrappers. The film’s edges are carefully aligned to ensure a smooth, consistent wrap.

3. Twisting the Ends

After the lollipop is wrapped, the machine moves to the twisting stage. This is where the machine's distinctive feature—the golden wire twist—comes into play.

Twisting Mechanism: The ends of the wrapper are twisted tightly using a specialized twisting tool. This ensures that the packaging stays secure and prevents the lollipop from falling out. The golden wire is used to tie the twisted ends, adding a premium touch to the packaging.

Golden Wire Application: The machine automatically dispenses the golden wire and twists it around both ends of the packaging. This golden wire not only adds an aesthetic appeal but also ensures the packaging is tightly sealed, preventing any contamination or air from entering.

This step is one of the key features that differentiates the Flat Lollipop Golden Wire Twist Packing Machine from other machines that might use basic plastic ties or heat seals.

4. Cutting and Sealing

Once the lollipop is tightly wrapped and the ends are twisted, the next step involves cutting and sealing the film. The machine uses a precision cutting tool to trim any excess film, ensuring a neat finish and consistent appearance.

Cutting: The excess packaging film is carefully cut off, leaving a clean edge that prevents any unwanted loose material.

Sealing: After cutting, the twisted ends are securely sealed, ensuring that the lollipop stays fresh and protected. This step is critical for ensuring that the packaging does not unravel or allow contamination.

At this point, the lollipop is fully packaged, with a golden wire twist closure and a flat, sleek design.

5. Quality Control and Packaging

As the lollipops move along the production line, they undergo a final quality control check. The machine is equipped with sensors to detect any irregularities in the packaging process, such as improperly wrapped lollipops or loose film.

Inspection: The system checks the tightness of the wrap and the golden wire twist to ensure every lollipop is perfectly sealed.

Packaging: Once approved, the wrapped lollipops are collected and placed into boxes or other forms of bulk packaging. The machine can also integrate with downstream packaging systems for bulk storage or shipping.

This automated process ensures that all the lollipops are consistently wrapped, properly sealed, and ready for shipment.

6. Cleaning and Maintenance

After the production run is complete, the Flat Lollipop Golden Wire Twist Packing Machine is cleaned and maintained to ensure long-lasting performance. The machine's modular design allows for easy access to key components, simplifying the cleaning and maintenance process.

Cleaning: The wrapping area, film feeders, and twisting mechanisms are cleaned to ensure hygiene standards are met.

Maintenance: Routine maintenance checks are performed to ensure that all components, especially the cutting tools and twisting mechanisms, are functioning properly.

This maintenance helps prevent any downtime, ensuring that the machine continues to run efficiently for extended periods.

Choosing the Right Flat Lollipop Golden Wire Twist Packing Machine for Your Business

Selecting the right Flat Lollipop Golden Wire Twist Packing Machine is an essential decision for any confectionery business, whether you're a startup or a well-established manufacturer. The machine you choose will significantly impact your production efficiency, product quality, and ultimately your profitability.

1. Production Volume

The first factor to consider when choosing a Flat Lollipop Golden Wire Twist Packing Machine is your production volume. If you're running a small to medium-sized business, a semi-automatic machine may be sufficient. These machines are more cost-effective and allow for manual intervention when necessary. However, if you’re scaling up or running a large-scale operation, a fully automatic machine is a better option, as it can handle high volumes and streamline your production process with minimal manual labor.

Low to Medium Volume: Semi-automatic or compact machines.

High Volume: Fully automatic or high-speed machines.

2. Machine Customization

Customization is an important consideration. Your business may need a machine that can handle different lollipop sizes or adapt to various film types and wrapping designs. Some machines offer the ability to adjust wrapping tension, speed, and even the type of wire used for the golden twist closure. Make sure the machine you choose can accommodate your product's unique packaging requirements.

Flexibility: Choose a machine that can be easily adjusted to suit different sizes and packaging materials.

3. Product Presentation and Aesthetics

The Flat Lollipop Golden Wire Twist Packing Machine is not only about functionality; it's also about enhancing the product's presentation. The golden wire twist adds a premium, elegant touch that appeals to consumers, particularly for premium or gift-oriented products. If your brand focuses on high-quality, visually appealing products, choosing a machine that delivers a professional and aesthetically pleasing packaging finish is crucial.

Aesthetic Appeal: Opt for a machine that enhances your product's visual appeal with premium wrapping and golden wire closure.

4. Space and Size Constraints

Consider the amount of space available in your production facility when choosing a packing machine. While larger machines are ideal for high-volume production, they require more space. On the other hand, compact versions offer flexibility for businesses with limited floor space but may have lower production capacities. Choose a machine that fits your available space without compromising on efficiency.

Limited Space: Compact or space-saving versions.

Larger Facilities: Fully automatic or high-speed machines for high volume.

5. Efficiency and Automation

Look for a Flat Lollipop Golden Wire Twist Packing Machine that offers high automation and efficiency. Machines that combine automated feeding, wrapping, twisting, and sealing minimize manual intervention, reduce human error, and increase overall production speed. For larger businesses, efficiency is crucial in keeping up with demand while maintaining quality. Ensure that the machine offers continuous operation, high-speed wrapping, and seamless integration with other production lines.

Automation: Fully automatic machines that streamline the entire process.

Speed and Efficiency: Machines designed for high-speed operations for businesses with high demand.

6. Maintenance and Durability

When investing in a packing machine, consider its maintenance requirements and durability. Machines with robust construction and easy-to-maintain components will save you time and money in the long run. Look for machines with modular designs that make cleaning and maintenance more straightforward. Additionally, ensure that the manufacturer provides after-sales support, spare parts availability, and service options to minimize downtime and keep your production running smoothly.

Easy Maintenance: Choose machines with accessible components and minimal downtime for cleaning and repairs.

Long-Term Durability: Invest in a machine with high-quality materials for consistent performance over time.

7. Environmental Considerations

Sustainability is an increasingly important factor for many businesses and consumers. If your company is committed to reducing its environmental footprint, consider a Flat Lollipop Golden Wire Twist Packing Machine that supports eco-friendly packaging materials, such as biodegradable or recyclable films. By choosing a machine that accommodates these materials, you can appeal to environmentally conscious consumers and meet industry standards for sustainability.

Eco-Friendly Options: Select machines that are compatible with biodegradable or recyclable films.

Factors to Consider When Choosing a Flat Lollipop Golden Wire Twist Packing Machine

| Factor | Description |

|---|---|

| Production Volume | Choose a semi-automatic machine for small volumes or a fully automatic machine for high-volume production. |

| Customization | Select a machine that offers flexibility for different sizes, films, and wrapping designs. |

| Aesthetic Appeal | Opt for a machine with golden wire twist closure for a premium look. |

| Space Constraints | Choose a compact machine if space is limited, or a larger one for high-volume production. |

| Efficiency and Automation | Look for high-speed, fully automated machines that reduce manual labor and increase production efficiency. |

| Maintenance and Durability | Invest in machines with easy maintenance, robust construction, and long-lasting components. |

| Environmental Considerations | Choose machines that accommodate eco-friendly films for sustainability. |

Why Choose Jiangsu Flying Dragon Flat Lollipop Golden Wire Twist Packing Machine

When selecting the right Flat Lollipop Golden Wire Twist Packing Machine for your business, Jiangsu Flying Dragon stands out as a top choice for several reasons:

1. Expertise in the Industry

Jiangsu Flying Dragon has extensive experience in manufacturing packaging machines for the confectionery industry. Our team has developed a deep understanding of market needs, ensuring that our Flat Lollipop Golden Wire Twist Packing Machines are designed to meet the specific demands of modern confectionery businesses.

2. Advanced Technology and Innovation

We integrate the latest technology into our machines, ensuring high performance, efficiency, and precision. Our machines are built with automation and speed in mind, offering continuous operation with minimal manual intervention. This is particularly beneficial for businesses looking to scale up production without compromising on quality.

3. Customization and Flexibility

At Jiangsu Flying Dragon, we understand that every business has unique needs. Our Flat Lollipop Golden Wire Twist Packing Machines can be easily customized to suit various product sizes, wrapping materials, and packaging designs. Whether you need adjustments in speed, tension, or film type, we can tailor the machine to your specifications.

4. Premium Quality Packaging

With the golden wire twist closure, our machines ensure that each lollipop is wrapped securely and attractively. The flat packaging design offers optimal space utilization, making your products more appealing on store shelves. This premium finish is ideal for businesses that want to elevate their product presentation and brand image.

5. Durable and Low-Maintenance

Our machines are built for durability and designed with ease of maintenance in mind. With modular components and user-friendly interfaces, cleaning and upkeep are simple and cost-effective. We also provide excellent after-sales support, ensuring that your machine continues to perform optimally for years to come.

6. Sustainability and Environmental Responsibility

We prioritize sustainability by offering machines that support eco-friendly packaging options, including biodegradable and recyclable films. By choosing Jiangsu Flying Dragon, you align your business with growing consumer demand for sustainable practices.

7. Comprehensive After-Sales Support

Jiangsu Flying Dragon provides comprehensive after-sales services, including installation, training, and ongoing support. We ensure that our customers are fully equipped to operate their machines effectively and efficiently. Our dedicated support team is always available to assist with troubleshooting and provide guidance when needed.

Why Choose Jiangsu Flying Dragon Flat Lollipop Golden Wire Twist Packing Machine

| Reason | Description |

|---|---|

| Industry Expertise | Extensive experience in confectionery packaging machinery ensures tailored solutions. |

| Advanced Technology | Integration of cutting-edge technology for automation, speed, and precision. |

| Customization Options | Machines can be tailored to meet unique production needs, including size and film type. |

| Premium Packaging | Ensures secure and attractive packaging with a golden wire twist and flat design. |

| Durability and Low Maintenance | Robust construction and easy-to-maintain design for long-term performance. |

| Sustainability | Machines compatible with eco-friendly, recyclable, and biodegradable packaging materials. |

| Comprehensive After-Sales Support | Full support, including installation, training, and troubleshooting to ensure optimal operation. |

Future Trends in Lollipop and Confectionery Packaging Machines

The packaging industry is continuously evolving, with advancements in technology, sustainability, and consumer preferences driving innovation. As the demand for more efficient, sustainable, and aesthetically pleasing packaging grows, manufacturers in the confectionery sector must stay ahead of these trends to maintain competitiveness. The lollipop and confectionery packaging machine sector is no exception, and several emerging trends are shaping the future of packaging technology.

1. Increased Automation and Smart Packaging

The future of confectionery packaging lies in automation. As businesses strive for greater efficiency and reduced labor costs, fully automated machines are becoming the industry standard. In particular, smart packaging technologies are gaining traction. These machines not only wrap and seal products but are also equipped with advanced sensors and artificial intelligence (AI) to optimize operations in real-time.

Predictive Maintenance: Future machines will be capable of predicting when parts need maintenance or replacement, reducing downtime and increasing productivity.

Data Integration: AI-driven machines can collect data throughout the production process, providing insights into efficiency, performance, and even consumer preferences.

Robust Automation: More manufacturers will move toward fully automated packaging lines, reducing the need for manual labor and enhancing consistency across production runs.

By embracing automation, businesses can scale operations, improve product consistency, and significantly reduce human error.

2. Sustainability and Eco-Friendly Packaging Materials

Sustainability is one of the most important trends influencing the lollipop and confectionery packaging sector. Consumers are increasingly seeking products with eco-friendly packaging that reduces environmental impact. As a result, packaging machine manufacturers are focusing on producing machines that can handle biodegradable, recyclable, or compostable materials.

Sustainable Films: The demand for eco-friendly films, such as biodegradable or plant-based materials, is expected to rise. Packaging machines will increasingly be designed to accommodate these sustainable materials without sacrificing packaging performance.

Reduced Plastic Use: As part of the global push to reduce plastic consumption, lollipop packaging machines will incorporate technologies to handle minimalist packaging designs or recyclable alternatives.

Circular Economy: The future will see more emphasis on circular economy models where materials are reused, recycled, or composted, and machines will evolve to support these processes seamlessly.

The adoption of sustainable packaging materials not only aligns with consumer demands but also helps businesses meet increasingly stringent environmental regulations.

3. Personalized and Customizable Packaging Solutions

With the rise of personalization in consumer goods, lollipop and confectionery packaging is also moving toward more customizable options. Packaging machines will need to offer more flexibility to allow brands to tailor the packaging according to specific customer demands or market trends.

Variable Printing and Design: Future packaging machines will incorporate digital printing technologies, enabling manufacturers to print custom logos, designs, and marketing messages directly onto the packaging without the need for separate printing presses.

Seasonal and Promotional Packaging: Machines will be able to quickly switch between packaging designs, allowing manufacturers to introduce seasonal or promotional packaging with minimal downtime.

Smaller Production Batches: As demand for limited-edition or niche products grows, packaging machines will need to accommodate smaller production runs without compromising efficiency.

By offering more customization options, confectionery manufacturers can meet the growing demand for personalized products and better connect with their target audience.

4. Integration with Smart Manufacturing Systems

The Internet of Things (IoT) is playing an increasing role in the manufacturing industry, and packaging machines are no exception. IoT-enabled packaging machines will be able to communicate with other machines and systems within the manufacturing environment, creating a fully integrated production line.

Real-Time Monitoring: IoT integration will enable real-time monitoring of machine performance, product quality, and material usage. This will allow manufacturers to quickly identify any issues and resolve them before they impact production.

Enhanced Supply Chain Efficiency: With real-time data sharing, packaging machines will provide insights that help optimize the entire supply chain, from material procurement to finished product distribution.

Remote Access: IoT-enabled packaging machines will offer remote troubleshooting and adjustment capabilities, allowing operators to monitor and control machines from any location.

By integrating packaging machines with smart manufacturing systems, companies can improve operational efficiency, reduce waste, and enhance product quality.

5. Advanced Packaging Formats

As consumers demand more convenience and variety, the lollipop packaging machine sector is also embracing new packaging formats. Future machines will be designed to accommodate diverse packaging styles that enhance product appeal while improving functionality.

Eco-Friendly Single-Serve Packs: Smaller, single-serve packages that cater to on-the-go consumption are becoming increasingly popular. Machines will need to handle these new packaging formats while maintaining speed and quality.

Multi-Pack and Group Packaging: There is growing demand for multi-pack formats, where multiple lollipops are packaged together for convenience. Future machines will be capable of grouping products with efficiency while maintaining individual product integrity.

Innovative Designs: Creative and functional packaging, such as resealable pouches or interactive packaging (e.g., QR codes, augmented reality), will gain traction. Packaging machines will need to evolve to handle these complex designs.

These new formats allow confectionery manufacturers to cater to evolving consumer preferences for convenience, functionality, and novelty.

6. Enhanced Hygiene Standards

Hygiene has always been crucial in food packaging, but the importance of cleanliness and safety in manufacturing has reached new levels due to global health concerns. Packaging machines will be designed to meet the highest hygiene standards and ensure food safety.

Easy-to-Clean Designs: Future machines will feature easy-to-clean surfaces and materials, ensuring that they meet the strictest health and safety regulations.

Food-Safe Materials: Machines will increasingly use food-safe components that comply with health regulations to prevent contamination.

Automation for Cleanliness: As automation increases, machines will be equipped with automatic cleaning systems to ensure that all components are sanitized without the need for manual intervention.

These innovations will help manufacturers maintain the highest standards of product safety, especially in the wake of increasing regulatory scrutiny.

7. Energy Efficiency and Reduced Carbon Footprint

As energy costs rise and environmental concerns become more pressing, the confectionery packaging industry is focusing on reducing its carbon footprint. Future lollipop packaging machines will be designed to be more energy-efficient, using less power while maintaining high production speeds.

Energy-Efficient Motors: Machines will use energy-efficient motors and technologies that minimize power consumption during operation.

Sustainable Manufacturing: Packaging machine manufacturers will increasingly adopt sustainable practices in their own production processes, helping reduce their environmental impact.

Heat Recovery Systems: Some machines may incorporate heat recovery systems, allowing them to recycle energy during the packaging process and reduce overall energy consumption.

By incorporating these energy-saving technologies, companies can reduce operating costs and contribute to environmental sustainability.

Flyloong Flat Lollipop Golden Wire Twist Packing Machine is more than just a tool for wrapping sweets—it's a game changer for manufacturers looking to elevate both their production efficiency and brand presentation. From automated precision to premium golden wire twists, this machine offers an unbeatable combination of functionality and aesthetic appeal.

Whether you are a high-volume producer or a boutique confectionery brand, investing in the right packing machine can make all the difference. As the market continues to demand both sustainability and innovation, this machine's ability to integrate eco-friendly materials and customizable packaging options ensures you stay ahead of the curve. Plus, with features that guarantee consistency, hygiene, and a polished finish, your products will stand out on shelves, meeting consumer expectations for quality and style.

If you want to maximize your production capabilities and leave a lasting impression on your customers, the Flat Lollipop Golden Wire Twist Packing Machine could be the key to unlocking your business's full potential. Keep up with the latest trends in confectionery packaging and watch your business grow with the right machinery in place. Ready to make your packaging more appealing and efficient? The next step starts here!

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home