What is an Automatic Rainbow Lollipop Machine?

An Automatic Rainbow Lollipop Machine is an innovative piece of equipment designed to automate the production of colorful, visually appealing rainbow lollipops. This machine simplifies the entire process of creating multi-colored lollipops by incorporating advanced technology, reducing manual labor, and improving efficiency and consistency. The automatic nature of the machine ensures that each lollipop is uniform in size, color, and quality, while also allowing for high-volume production, which is crucial for large-scale candy manufacturers.

Importance and Appeal of Rainbow Lollipops in the Candy Industry

Rainbow lollipops have become a quintessential symbol of fun, excitement, and nostalgia in the candy industry. Their vibrant colors and playful designs make them a favorite among children and adults alike. Over the years, these colorful treats have not only captured the imagination of candy lovers but have also played a key role in shaping marketing strategies and product offerings in the confectionery industry.

1. Visual Appeal and Consumer Attraction

One of the primary reasons rainbow lollipops hold such broad appeal is their striking visual presentation. The multiple vibrant colors arranged in swirls or stripes are eye-catching and attractive. Bright colors are known to stimulate the appetite and evoke feelings of joy, which is why candy manufacturers use them to create products that stand out on store shelves. The allure of rainbow-colored lollipops, with their playful and cheerful look, draws in consumers, especially younger ones, who are naturally attracted to vivid hues.

The rainbow design represents a variety of flavors, making the product even more intriguing. Consumers often perceive the diverse colors as an invitation to a unique and enjoyable taste experience, further adding to the lollipop's charm.

2. Nostalgia and Emotional Connection

Rainbow lollipops carry with them a sense of nostalgia, reminding people of simpler times, often linked to childhood memories. Whether it's a treat from a carnival, a fair, or a special gift, these lollipops have long been associated with moments of happiness and celebration. For many, they evoke fond memories of birthday parties, summer days, or trips to candy stores.

This emotional connection is significant for candy brands aiming to tap into the emotions of consumers. Nostalgia-driven marketing is a powerful tool in the candy industry, and rainbow lollipops, with their timeless appeal, serve as a perfect vessel for connecting with consumers on a deeper emotional level.

3. Versatility and Popularity Across Demographics

While rainbow lollipops are primarily marketed to children, their appeal extends far beyond this group. Adults are drawn to their whimsical nature, and the colorful candy can also be seen as a playful, indulgent treat for people of all ages. As a result, rainbow lollipops can be effectively marketed to a broad demographic, from children at birthday parties to adults at festivals or in novelty gift boxes.

Additionally, rainbow lollipops are versatile in terms of packaging and branding. They can be sold individually or in bulk, wrapped in shiny foil or cellophane, and offered in different sizes, making them suitable for various occasions such as corporate events, holidays, and seasonal promotions. This adaptability allows manufacturers to cater to a wide range of consumer preferences.

4. Popularity in Seasonal and Promotional Campaigns

Rainbow lollipops are often featured in seasonal and promotional campaigns due to their vibrant colors and festive appeal. During holidays like Christmas, Halloween, or Easter, these lollipops are frequently part of themed candy packages, gift baskets, and party favors. Their colorful appearance aligns perfectly with the celebratory nature of these occasions, making them a staple in seasonal candy collections.

In addition to holidays, rainbow lollipops are also a popular choice for brand promotions, particularly for companies looking to add a playful or lighthearted element to their campaigns. Their visual appeal and association with fun and happiness make them an ideal promotional product for attracting attention, whether at an event, trade show, or in a retail setting.

5. Health-Conscious Trends and Innovations

As consumer preferences evolve and health-conscious trends continue to influence the candy industry, manufacturers are exploring ways to make rainbow lollipops a more inclusive treat. This has led to innovations such as sugar-free, organic, and gluten-free versions of rainbow lollipops, making them more accessible to a wider audience.

The demand for products that cater to specific dietary needs has spurred the development of healthier alternatives while maintaining the eye-catching rainbow design. These innovations not only meet the needs of modern consumers but also ensure that the rainbow lollipop continues to appeal to various market segments, including those with dietary restrictions.

6. Rainbow Lollipops in the Marketing World

The visual appeal of rainbow lollipops also makes them an effective marketing tool. Their bold, colorful appearance lends itself well to social media marketing and influencer collaborations. The lollipop's bright, playful design is often shared across Instagram, Facebook, and other platforms, where candy brands gain significant exposure. Consumers are more likely to post pictures of brightly colored lollipops, leading to increased brand visibility.

Moreover, rainbow lollipops have been used by companies in creative marketing campaigns, often featured as limited-edition flavors or seasonal items. The connection between these colorful treats and exclusive offers builds a sense of excitement around the product, creating a buzz and driving consumer demand.

Features of the Automatic Rainbow Lollipop Machine

The Automatic Rainbow Lollipop Machine is a highly advanced piece of equipment designed to automate the production of rainbow lollipops, a favorite treat known for their vibrant, multi-colored appearance. With the growing demand for mass-produced, high-quality confections, these machines offer a significant advantage by increasing efficiency, consistency, and speed in candy manufacturing.

1. Multi-Color Production Capability

One of the most prominent features of an Automatic Rainbow Lollipop Machine is its ability to create lollipops with vibrant multi-colored layers. The machine is equipped with specialized components that enable it to combine different colored sugar mixtures in a precise order, creating the iconic rainbow effect. Whether it's a spiral, striped, or concentric design, the machine ensures that each lollipop is visually striking and consistent in its color pattern.

This feature is crucial for candy manufacturers aiming to produce large quantities of rainbow lollipops that retain the same eye-catching appeal, which would be challenging to achieve manually. The multi-color production also allows for creative variations in the final product, appealing to different consumer tastes and preferences.

2. High-Speed Production

The Automatic Rainbow Lollipop Machine is designed for high-volume production, capable of producing a large number of lollipops within a short period. The automation significantly reduces the time and labor required to make these colorful treats, ensuring faster turnaround times for manufacturers. By streamlining the entire process from mixing to molding, the machine enables manufacturers to meet growing market demands without compromising quality.

This high-speed production feature is essential for commercial candy manufacturers looking to scale up their operations. The machine's efficiency allows for continuous production, making it a valuable investment for companies aiming to increase output while reducing labor costs.

3. Precision Molding System

Another critical feature is the precision molding system, which ensures that each lollipop is consistent in shape and size. The machine automatically fills the molds with the candy mixture, ensuring uniformity in every batch. Whether the mold is for a standard round lollipop, a heart shape, or any other custom design, the molding system delivers precise results every time.

The precision of this system also extends to the distribution of the rainbow layers. Each layer is applied evenly, creating lollipops with sharp, defined color boundaries and a smooth surface finish. This ensures that the final product is both visually appealing and structurally sound.

4. Integrated Cooling System

Once the lollipops are formed, they must be cooled and set in their final shape. The integrated cooling system in the Automatic Rainbow Lollipop Machine helps speed up this process. It uses a controlled cooling environment to lower the temperature of the lollipops, ensuring that they solidify quickly while maintaining their shape and color integrity.

The cooling system ensures that lollipops are ready for packaging without any distortion or melting. This feature is vital for maintaining the quality of the finished product, especially when dealing with intricate, multi-layered designs that require careful temperature control to avoid any color blending or deformation.

5. Automatic Wrapping and Packaging

To further streamline the production process, many Automatic Rainbow Lollipop Machines come with an integrated wrapping and packaging system. Once the lollipops are cooled and solidified, the machine automatically wraps them in protective plastic or paper, ready for distribution.

This feature minimizes the need for manual labor and reduces the risk of contamination during handling. The automatic wrapping system can be adjusted to fit various packaging materials and sizes, ensuring that each lollipop is securely sealed and ready for retail. This makes the machine not only efficient but also highly adaptable to different packaging requirements.

6. Customizable Settings for Different Designs

The Automatic Rainbow Lollipop Machine allows manufacturers to adjust settings based on the design and size of the lollipops they wish to create. Whether it's the number of color layers, the thickness of each layer, or the size of the lollipop, the machine can be customized to meet specific production needs.

This feature offers flexibility for candy makers who want to experiment with new designs or produce limited-edition lollipops. The ability to switch between different molds, patterns, and sizes allows businesses to diversify their product offerings and cater to specific consumer preferences.

7. Easy-to-Use Control Panel

The machine is typically equipped with an easy-to-use control panel that allows operators to set parameters such as temperature, speed, and mold configuration. This intuitive interface ensures that even operators with limited technical knowledge can quickly learn to operate the machine and make adjustments as needed.

The control panel also provides real-time monitoring of the machine’s performance, alerting operators to any issues such as overheating or malfunctions. This enhances the overall ease of use, ensuring that production runs smoothly with minimal downtime.

8. Hygienic Design and Easy Cleaning

Maintaining hygiene is essential in any food manufacturing process, and the Automatic Rainbow Lollipop Machine is designed with cleanliness in mind. The machine is made with food-safe, easy-to-clean materials, ensuring that there is no risk of contamination during the candy-making process. Components that come into contact with the candy mixture are easily removable for cleaning, and the design minimizes crevices where food residues could accumulate.

This hygienic design not only meets food safety standards but also makes maintenance and cleaning more efficient, reducing downtime between production runs and ensuring that the machine remains in optimal working condition.

9. Energy Efficiency

In addition to its speed and precision, the Automatic Rainbow Lollipop Machine is designed to be energy-efficient, helping manufacturers lower operational costs. The machine optimizes energy use without compromising the quality of the lollipops, making it a cost-effective solution for businesses seeking to reduce their environmental footprint while improving production efficiency.

Applications of the Automatic Rainbow Lollipop Machine in the Candy Industry

The Automatic Rainbow Lollipop Machine has revolutionized the production of one of the most colorful and beloved confectioneries—rainbow lollipops. These vibrant treats have captured the imagination of consumers worldwide, becoming a staple in the candy industry. The automated process provided by these machines has opened up numerous applications that benefit manufacturers, from increasing efficiency to enhancing product consistency.

1. High-Volume Production for Retail Market

One of the primary applications of the Automatic Rainbow Lollipop Machine is in the mass production of rainbow lollipops for the retail market. Candy manufacturers use these machines to produce large quantities of lollipops, catering to high consumer demand. Whether it's for supermarkets, candy stores, or online retail platforms, the machine allows for the continuous production of colorful, uniform lollipops that meet the needs of both small and large-scale businesses.

The machine's high-speed production capabilities make it an essential tool for manufacturers who need to produce large batches of candy efficiently. By automating the entire process, manufacturers can meet deadlines and deliver products in a timely manner, ensuring that there's no delay in product availability, especially during peak sales periods like holidays or seasonal events.

2. Customization for Special Events and Promotions

The flexibility of the Automatic Rainbow Lollipop Machine also enables manufacturers to create customized lollipops for special events and promotional campaigns. Whether it's for themed parties, festivals, or corporate branding initiatives, the machine allows for the creation of lollipops in unique shapes, colors, and designs.

The customization can extend beyond the rainbow color scheme to include the ability to add logos, messages, or patterns that align with the theme of the event. For instance, companies often produce limited-edition rainbow lollipops for holidays, anniversaries, or product launches, making them an ideal item for marketing campaigns and giveaways. The ease of producing customized designs ensures that these special edition products stand out in the marketplace, attracting attention and boosting sales.

3. Candy Variety Expansion for Product Lines

The Automatic Rainbow Lollipop Machine gives manufacturers the ability to expand their product lines with new variations of rainbow lollipops. Through adjustments in the machine's settings, manufacturers can experiment with different flavor combinations, texture variations, or even the addition of fillings, such as chocolate or fruit gels, to create unique versions of rainbow lollipops.

By using the machine's customizable features, manufacturers can introduce a variety of rainbow lollipop products that appeal to diverse consumer preferences. For example, offering sugar-free, organic, or gluten-free rainbow lollipops allows companies to cater to health-conscious consumers or those with dietary restrictions, broadening the market reach for their candy products.

4. Efficient Seasonal and Holiday Candy Production

Rainbow lollipops are a popular treat during holidays such as Christmas, Halloween, Easter, and summer festivals. The automatic machine's ability to produce high quantities of lollipops with consistent quality makes it an ideal solution for meeting the seasonal demand for candy during these times.

During peak seasons, candy companies can utilize the machine to ramp up production, ensuring they have enough stock to meet the influx of customer orders. For instance, rainbow lollipops are often sold as part of holiday gift bags, party favors, or as stand-alone treats in festive packaging. By automating the production process, companies can quickly produce the colorful candies in time for these events, helping them capitalize on the seasonal demand.

5. Specialized Lollipops for Gift Markets

Rainbow lollipops also have a significant presence in the gift market, where they are often sold in decorative packaging for special occasions like birthdays, anniversaries, or weddings. The Automatic Rainbow Lollipop Machine can produce lollipops of different shapes, sizes, and designs, making them perfect for use in gift boxes or gift baskets.

Lollipops, particularly those that are visually stunning, make for a delightful and fun gift. The machine's ability to create unique and intricate designs, along with its ability to produce small batches of customized lollipops, allows manufacturers to enter the gift market and offer personalized products that align with consumer tastes and trends.

6. Catering to the Novelty Candy Market

Rainbow lollipops have long been associated with novelty candy products, which are often marketed to specific age groups or for special experiences. These novelty lollipops are typically larger, more colorful, and more creative than the standard candy. Examples include oversized rainbow lollipops, spiral-shaped versions, or lollipops with embedded messages or images.

The Automatic Rainbow Lollipop Machine enables manufacturers to cater to this niche market by providing the means to produce larger, more intricate, and imaginative lollipop designs. These lollipops are often sold at amusement parks, theme parks, fairs, and festivals, where novelty and novelty-themed products attract large crowds.

7. Themed Confectionery for Movie and Media Tie-ins

In the media and entertainment sectors, movie and media tie-ins are a popular marketing strategy. Rainbow lollipops, with their bright, colorful appeal, can be easily adapted to tie into movie themes, TV shows, or even viral trends. Candy manufacturers can collaborate with film studios or media companies to create limited-edition rainbow lollipops featuring designs inspired by characters or scenes from popular films or TV shows.

The Automatic Rainbow Lollipop Machine can be used to produce these themed lollipops quickly and efficiently, allowing for mass distribution. By incorporating movie-themed colors, shapes, and branding, these lollipops serve as fun merchandise and create excitement among fans, further promoting both the media content and the candy itself.

8. Health-Conscious Candy Production

As the demand for healthier alternatives continues to rise, manufacturers are using the Automatic Rainbow Lollipop Machine to create health-conscious versions of rainbow lollipops. Sugar-free, organic, and natural ingredient-based rainbow lollipops are becoming increasingly popular among health-conscious consumers.

These machines allow manufacturers to use alternative sweeteners, natural colorants, and organic ingredients to produce lollipops that meet the needs of those with dietary restrictions or preferences. The ability to produce such candies at scale using the automatic machine ensures that these health-conscious products are readily available to meet consumer demand without sacrificing the vibrant colors and fun appeal of traditional rainbow lollipops.

Benefits of Using an Automatic Rainbow Lollipop Machine

The Automatic Rainbow Lollipop Machine has revolutionized the production of rainbow lollipops, offering candy manufacturers a wide array of advantages that enhance productivity, efficiency, and creativity. This advanced piece of equipment automates the entire candy-making process, from mixing the ingredients to packaging the finished product, ensuring consistency and high-quality results.

1. Increased Production Speed

One of the primary benefits of using an Automatic Rainbow Lollipop Machine is its ability to significantly increase production speed. By automating the entire process, the machine drastically reduces the time needed to produce a batch of rainbow lollipops. Traditional manual methods are time-consuming and labor-intensive, whereas automation enables manufacturers to produce large quantities of lollipops in a fraction of the time.

The machine's continuous operation ensures a steady flow of product, meeting the growing demand in a faster and more efficient manner. This enhanced speed not only helps to meet high seasonal demand but also boosts overall production capacity, making it ideal for both small-scale and mass production.

2. Consistent Product Quality

The consistency of product quality is another major advantage of the Automatic Rainbow Lollipop Machine. Manual production processes can result in uneven quality, as human error and variability can affect each batch. However, the machine's automated system ensures that each rainbow lollipop is uniform in size, color, texture, and design.

By maintaining precise control over the temperature, ingredient mixing, molding, and layering, the machine guarantees that every lollipop has the same vibrant colors, smooth texture, and sturdy structure. This consistency is crucial for maintaining customer satisfaction and building brand reliability, especially when producing products on a large scale.

3. Enhanced Precision in Design and Appearance

The Automatic Rainbow Lollipop Machine excels in producing precise, intricate designs that would be difficult to achieve manually. Rainbow lollipops are known for their eye-catching, multi-colored patterns, and the machine's advanced technology ensures that the layering process is executed with perfect precision. Whether the design is a simple spiral or a complex concentric pattern, the machine can replicate it flawlessly with each batch.

This capability allows manufacturers to create visually appealing lollipops that are consistent and meet the aesthetic expectations of consumers. The machine's precise control over the color layers also enables the creation of custom designs, making it ideal for producing special edition products, personalized gifts, or seasonal treats.

4. Reduced Labor Costs

Automating the production of rainbow lollipops leads to a significant reduction in labor costs. The Automatic Rainbow Lollipop Machine requires minimal manual intervention, meaning that manufacturers can reduce the number of staff needed to oversee production. This not only lowers labor expenses but also allows businesses to reallocate their workforce to other areas, such as marketing, sales, or customer service.

By reducing the need for manual labor, companies can also improve efficiency, minimize human error, and focus on more value-added tasks. Additionally, the machine's streamlined process reduces the chances of costly mistakes, such as misprints or defective products, which could otherwise lead to waste and additional labor costs.

5. Customization and Flexibility

The customization capabilities of the Automatic Rainbow Lollipop Machine offer manufacturers a high level of flexibility. The machine can be adjusted to create different shapes, sizes, and color patterns, allowing manufacturers to cater to a variety of customer preferences. Custom lollipops can be designed for holidays, corporate events, promotions, or even unique flavor combinations.

For example, the machine can produce rainbow lollipops with specific colors and designs that align with a brand's identity or a special marketing campaign. It also allows for the creation of limited-edition or seasonal products, giving businesses the flexibility to adapt to changing consumer tastes and market trends.

6. Streamlined Packaging Process

In addition to producing high-quality lollipops, the Automatic Rainbow Lollipop Machine typically includes an integrated packaging system that automatically wraps and seals the lollipops once they are finished. This eliminates the need for manual packaging, which can be time-consuming and labor-intensive.

The automated packaging process ensures that each lollipop is properly wrapped, sealed, and ready for distribution with minimal handling. This not only increases the efficiency of the production line but also maintains hygiene and reduces the risk of contamination during the packaging phase.

7. Increased Product Variety

The versatility of the Automatic Rainbow Lollipop Machine enables manufacturers to produce a wide range of lollipop varieties with different flavors, sizes, and designs. Manufacturers can experiment with multi-layered lollipops, infuse different flavors into each color layer, or add fillings such as chocolate or fruit gel to enhance the product's appeal.

This ability to create diverse products is particularly valuable in catering to niche markets, such as health-conscious consumers looking for sugar-free or organic options. It also allows for the introduction of new products that can keep the brand fresh and relevant in a competitive market.

8. Scalability for High-Demand Periods

During high-demand periods such as holidays, promotional campaigns, or special events, the Automatic Rainbow Lollipop Machine can quickly scale up production to meet the increased demand. The ability to operate at full capacity without sacrificing quality makes it an ideal tool for manufacturers who need to produce large volumes of rainbow lollipops on short notice.

This scalability is particularly important for businesses that need to adapt to market fluctuations or limited-time offers. It allows manufacturers to ramp up production quickly while maintaining consistency and minimizing lead times.

9. Improved Hygiene and Safety Standards

Maintaining high hygiene standards is essential in food production, and the Automatic Rainbow Lollipop Machine helps ensure that the manufacturing process is sanitary and safe. The machine is designed with food-grade materials and is easy to clean, reducing the risk of contamination.

With fewer human hands touching the product, there is a lower chance of introducing bacteria or impurities. The automation of the entire process, from mixing to packaging, also minimizes the handling of ingredients and finished products, ensuring a safer and more hygienic production environment.

10. Long-Term Cost Efficiency

Investing in an Automatic Rainbow Lollipop Machine can offer long-term cost savings. While the initial investment may be significant, the machine’s ability to produce large volumes of high-quality lollipops with minimal labor and operational costs makes it a cost-effective solution in the long run.

The efficiency gains, reduced waste, and increased production capacity make it a wise investment for manufacturers looking to stay competitive in the growing candy industry. Over time, the machine’s benefits far outweigh the initial costs, leading to greater profitability and market growth.

Types of Automatic Rainbow Lollipop Machine

The Automatic Rainbow Lollipop Machine is a highly versatile and essential tool for the candy industry, particularly for creating visually stunning, multi-colored lollipops. Various types of these machines exist, each tailored to different production needs, capacities, and customization options. These machines have revolutionized the candy-making process, enabling manufacturers to produce high-quality, colorful lollipops at an efficient pace.

1. Single-Layer Rainbow Lollipop Machine

The Single-Layer Rainbow Lollipop Machine is designed for producing basic rainbow lollipops with a single color pattern or simple color layers. These machines typically handle straightforward production needs, making them ideal for small to medium-scale manufacturers or businesses focused on producing simple, yet attractive, lollipops.

This type of machine typically allows the creation of rainbow lollipops with a standard multi-colored swirl, but without the complex layering or intricate designs seen in higher-end models. Single-layer machines are easy to operate, cost-effective, and perfect for businesses that want to maintain efficient production without the need for elaborate design customization.

2. Multi-Layer Rainbow Lollipop Machine

For manufacturers seeking to create complex and multi-colored lollipops, the Multi-Layer Rainbow Lollipop Machine is the optimal choice. This machine allows the production of lollipops with several layers of different colors and flavors. Each layer can be made from different ingredients or colors, offering a more intricate and eye-catching final product.

The ability to create multi-layered lollipops adds a unique touch to the candy-making process, with each layer contributing its own vibrant color or distinct flavor. These machines are ideal for large-scale manufacturers or businesses that wish to cater to premium markets, as the lollipops produced are more visually stunning and often command a higher price.

3. Double-Sided Rainbow Lollipop Machine

The Double-Sided Rainbow Lollipop Machine is a specialized machine designed to create lollipops that are rainbow-colored on both sides. This type of machine is ideal for producing lollipops that not only have vibrant multi-colored layers on one side but also feature a matching design on the other. Double-sided lollipops are popular in novelty markets, particularly for use in gift bags or as party favors.

These machines are typically used for creating oversized or uniquely shaped lollipops. They offer the flexibility to produce lollipops with different designs or color patterns on each side, which can add a level of novelty and creativity that appeals to consumers looking for something distinctive.

4. Customized Design Rainbow Lollipop Machine

For businesses looking to personalize their products, the Customized Design Rainbow Lollipop Machine allows manufacturers to create lollipops with intricate designs, logos, or patterns embedded into the candy. These machines are highly flexible and allow for the customization of each lollipop’s appearance by using molds and precise temperature control to ensure the design is perfectly replicated.

The ability to imprint logos or unique patterns into the candy makes this machine particularly beneficial for promotional items and branded candy. It’s perfect for marketing campaigns, corporate gifts, and events where a specific design is required for each batch of lollipops.

5. High-Capacity Automatic Rainbow Lollipop Machine

The High-Capacity Automatic Rainbow Lollipop Machine is designed for large-scale production, capable of producing significant volumes of lollipops per hour. This machine type is ideal for businesses that need to meet high demands in a short period, such as during peak seasons or for global distribution.

These machines are often equipped with more advanced automation features, such as automatic molding, wrapping, and packaging systems, making them incredibly efficient for businesses that need to produce thousands of lollipops in a limited amount of time. High-capacity machines are built for continuous operation and are suited for manufacturers with high-volume production needs.

6. Eco-Friendly Rainbow Lollipop Machine

With increasing awareness of environmental impact, some manufacturers are turning to eco-friendly machines that focus on reducing waste and energy consumption. The Eco-Friendly Rainbow Lollipop Machine incorporates energy-efficient technology and processes that minimize the environmental footprint of candy production.

These machines often use sustainable materials and incorporate practices that reduce energy usage and product waste. Manufacturers interested in appealing to environmentally conscious consumers or improving the sustainability of their production processes often opt for this type of machine to align with modern industry standards.

7. Handheld and Small-Scale Rainbow Lollipop Machine

For small-scale producers or businesses just starting in the candy-making industry, the Handheld or Small-Scale Rainbow Lollipop Machine is an excellent choice. These machines are compact, lightweight, and easy to operate, making them suitable for smaller production runs or artisanal candy businesses.

These machines allow for a more hands-on approach to production, where manufacturers can experiment with colors, flavors, and designs. While they are not as fast as larger machines, they are affordable and allow small businesses to enter the market without the need for a large initial investment. Handheld machines are perfect for producing smaller quantities of premium or artisanal rainbow lollipops.

8. Multi-Flavor Rainbow Lollipop Machine

The Multi-Flavor Rainbow Lollipop Machine is designed to produce rainbow lollipops that feature different flavors within each color layer. This machine allows manufacturers to mix various flavors into the candy, creating a unique tasting experience for consumers.

With the ability to create flavor profiles such as tropical fruits, chocolate, or sour and sweet combinations, this machine is perfect for creating innovative products that stand out in the market. Multi-flavor lollipops are popular among consumers looking for new and exciting taste combinations, and this machine helps manufacturers meet that demand efficiently.

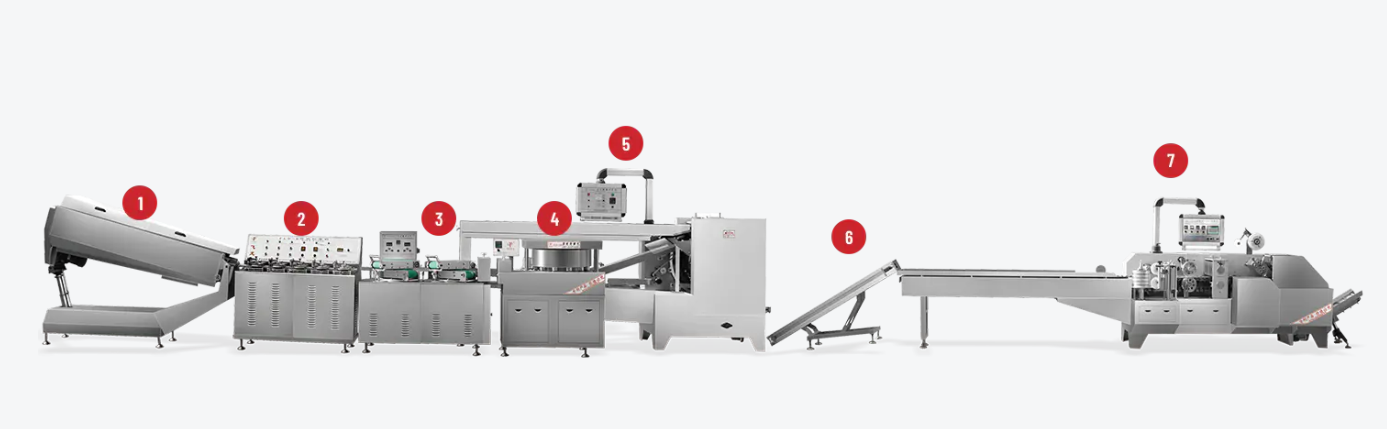

9. Fully Automated Rainbow Lollipop Production Line

For companies aiming for full-scale automation of the entire production process, the Fully Automated Rainbow Lollipop Production Line is the ultimate solution. This machine integrates all stages of production, from the mixing of ingredients to the molding, cooling, and packaging of the lollipops.

The fully automated line ensures a seamless process, reducing the need for human labor at every step. This type of machine is ideal for businesses that want to automate their entire lollipop production, improving efficiency and minimizing human error. With advanced control systems, manufacturers can monitor every stage of production, making adjustments as needed to ensure the highest quality output.

How the Automatic Rainbow Lollipop Machine Works

The Automatic Rainbow Lollipop Machine is a marvel of engineering designed to automate the entire process of creating vibrant, multi-colored lollipops. From mixing ingredients to packaging the finished product, this machine significantly improves the efficiency, consistency, and speed of production.

1. Ingredient Preparation and Mixing

The first step in the process is the preparation of ingredients. The machine starts by receiving the primary components, such as sugar, glucose syrup, flavoring agents, and colorants. These ingredients are mixed together in the machine's mixing chamber, where precise temperature control and speed settings are used to ensure the perfect texture and consistency for the lollipop mixture.

The mixture is heated to a specific temperature to dissolve the sugar and achieve the right viscosity. Colorants and flavorings are added during this stage to create the distinct layers of the rainbow lollipop. Depending on the machine model, different colors and flavors can be mixed in separate compartments, allowing for the creation of multi-flavored and multi-colored lollipops.

2. Molding and Shaping

Once the ingredients are mixed, the next step is the molding and shaping of the lollipops. The liquid mixture is transferred into the molding chamber, where it is poured into specialized molds that shape the candy. For a rainbow lollipop, the machine uses a series of nozzles and layers to deposit the mixture in a specific order to create the desired rainbow effect.

The machine can create multiple layers, each representing a different color of the rainbow. It carefully controls the layering process, ensuring that each color layer is evenly distributed, and that the lollipop maintains a uniform shape. The lollipop sticks are also inserted at this stage, with the machine ensuring that they are properly placed in the center of the candy.

3. Cooling and Solidification

Once the lollipops are molded, they need to be cooled to set the candy and solidify its shape. The cooling process is essential for ensuring that the lollipops hold their form and do not become deformed or sticky.

The Automatic Rainbow Lollipop Machine includes a cooling conveyor system that helps speed up this process. The freshly molded lollipops are transported through a cooling tunnel where air circulation is used to bring down the temperature of the lollipops quickly and efficiently. This ensures that the candy hardens without any imperfections, allowing for easier handling and packaging.

4. Cutting and Shaping (If Needed)

For machines that produce larger or uniquely shaped rainbow lollipops, an additional step may be involved, such as cutting or shaping. If the lollipops are designed in special forms (e.g., oversized, heart-shaped, or with intricate patterns), the machine may have cutting mechanisms that trim the candy to the desired size or shape.

These shaping mechanisms ensure that each lollipop matches the exact specifications for both size and form, whether the design is simple or more elaborate. This is particularly useful for novelty items and promotional candies that need to meet specific visual requirements.

5. Wrapping and Packaging

After the lollipops have cooled and solidified, they move to the final stage of production: wrapping and packaging. The Automatic Rainbow Lollipop Machine typically includes an integrated wrapping system that automatically wraps each lollipop in protective film to keep it clean, fresh, and intact during transportation.

The wrapping system is capable of wrapping lollipops in a variety of materials, including cellophane or plastic film, and may also be customizable for specific packaging needs. For added convenience, the machine may also package the wrapped lollipops into boxes or bags, ready for distribution.

6. Quality Control and Inspection

Throughout the entire process, the Automatic Rainbow Lollipop Machine is equipped with quality control systems that monitor the production flow. Sensors are used to detect any irregularities in the color layers, shape, or size of the lollipops. If any issues are detected, the machine can automatically reject the defective pieces to ensure that only high-quality lollipops proceed to the wrapping and packaging stage.

Automated inspection ensures that each lollipop is uniform in appearance and meets the required standards for taste and presentation. This helps reduce human error and ensures that every batch of rainbow lollipops is consistent.

7. Output and Final Adjustment

Once the lollipops are packaged and ready for shipment, the machine outputs them in an organized manner, often stacking the final products on trays or into cartons for easy handling. Some machines even have the capability to label the packages with product information, batch numbers, and expiration dates.

In addition to the automation of the production and packaging processes, the machine can be programmed to adjust production speeds and customize candy designs. This flexibility allows manufacturers to tailor the production process based on specific product requirements or consumer demand.

How to Choose the Right Automatic Rainbow Lollipop Machine

Choosing the right Automatic Rainbow Lollipop Machine is a critical decision for manufacturers in the candy industry, as it directly affects production efficiency, product quality, and overall business success. With a wide range of machines available, it's essential to consider several factors to ensure that the selected machine fits the specific needs of your production process.

1. Determine Your Production Volume Requirements

The first step in selecting an automatic rainbow lollipop machine is to assess your production volume requirements. If you are a small business or a startup, a machine with a lower production capacity might be sufficient. However, if you're operating at a large scale or expect significant growth, opting for a machine with higher throughput may be necessary.

Consider whether your demand is steady or seasonal. High-capacity machines can meet large, fluctuating orders, especially during peak seasons like holidays or promotions. Evaluating your current and projected production needs will help determine the right machine size and production capabilities.

2. Machine Customization and Design Flexibility

If you are aiming to produce a wide range of rainbow lollipops with varying shapes, colors, and flavors, look for a machine that offers customization options. The ability to adjust the number of color layers, mix different flavors in each layer, or create unique shapes is essential for standing out in a competitive market.

Machines that allow for design flexibility—such as the ability to switch between standard rainbow patterns and more intricate designs—can help you cater to a diverse range of consumer preferences. For example, machines with customizable molds or design options will give you the creative freedom to produce limited-edition lollipops, seasonal designs, or novelty items.

3. Speed and Efficiency

The speed and efficiency of the machine are paramount, especially when production runs need to be completed quickly. High-efficiency machines are essential for maintaining consistent output, ensuring that large volumes of rainbow lollipops are produced at optimal speed while minimizing downtime.

Consider whether the machine has automatic adjustment capabilities, such as adjusting production speed based on batch size or production flow. Machines with integrated cooling and packaging systems can also save time by streamlining the entire production process, reducing the need for manual labor in between stages.

4. Reliability and Durability

The reliability and durability of the machine are critical factors, especially when it comes to maintaining production schedules. A well-built machine will be less likely to experience breakdowns, ensuring that your production process remains uninterrupted. Look for machines made with high-quality materials that can withstand long hours of operation without showing signs of wear and tear.

Additionally, consider the maintenance requirements of the machine. Machines that are easy to clean and maintain will reduce downtime and increase the lifespan of the equipment. A reliable machine should come with a strong after-sales service and support system to address any issues that arise during operation.

5. Automation Level and Integration

The level of automation is another important consideration. Fully automated machines are ideal for large-scale operations because they minimize the need for manual labor, reduce human error, and ensure consistency across every batch of lollipops. Look for machines that can handle multiple stages of production, including mixing, molding, cooling, and packaging.

Some machines can integrate with other production systems or factory lines, offering the ability to streamline operations further. If your production line is already automated, consider a machine that can seamlessly integrate into your existing workflow to ensure smooth operations.

6. Product Consistency and Quality Control

An automatic rainbow lollipop machine should offer excellent product consistency to ensure that every lollipop produced is of the highest quality. Look for a machine that incorporates quality control systems, such as sensors and automatic inspections, to detect defects in size, shape, or color.

Product consistency is crucial in the candy industry, where customers expect the same high standard every time they purchase a product. A machine that can consistently produce uniform lollipops with minimal imperfections will help build consumer trust and increase brand loyalty.

7. Packaging and Wrapping Capabilities

Another essential factor to consider is whether the machine includes packaging and wrapping capabilities or if this requires separate equipment. Some automatic rainbow lollipop machines come with built-in wrapping systems that automatically wrap the lollipops and seal them for freshness. This not only increases efficiency but also reduces labor costs associated with manual wrapping.

Look for machines that can accommodate various packaging types, whether it’s individual wrappers or bulk packaging, depending on your market requirements. Additionally, machines with adjustable wrapping speeds and packaging designs can give you the flexibility to adapt to changing consumer needs or promotional campaigns.

8. Ease of Operation and Training

A machine that is easy to operate is essential for ensuring smooth production runs. Look for machines with user-friendly interfaces, clear instructions, and intuitive controls. Even if your staff isn't highly experienced, the machine should be easy to set up and operate with minimal training.

Training and technical support should also be factored in when choosing a machine. Opt for a manufacturer that provides comprehensive training resources and readily available customer support in case technical assistance is required. This will help minimize downtime and ensure smooth operations from day one.

9. Cost and Return on Investment

Finally, consider the cost of the machine in relation to the potential return on investment (ROI). While higher-end machines with advanced features might come with a larger initial investment, they can help increase production efficiency and quality, leading to higher profits in the long term.

Consider the machine's potential to reduce labor costs, increase output, and minimize waste. A well-chosen machine will help boost your production capacity and allow you to offer a higher-quality product to your customers, ultimately increasing profitability over time.

10. Environmental Considerations

With growing consumer demand for sustainable products, it's important to select a machine that minimizes environmental impact. Look for machines designed with energy-efficient technology that reduces power consumption during the production process. Machines that utilize eco-friendly materials or offer waste-reduction features, such as recycling excess candy or using biodegradable wrapping, are also worth considering for sustainability-conscious businesses.

Maintenance and Longevity of the Automatic Rainbow Lollipop Machine

Ensuring the maintenance and longevity of an Automatic Rainbow Lollipop Machine is essential for preserving its performance, preventing costly downtime, and maximizing return on investment. These machines are designed to operate continuously for long hours, producing large volumes of lollipops, but without proper care, even the most advanced equipment can experience wear and tear.

1. Regular Cleaning and Sanitation

One of the most important maintenance practices is regular cleaning. Since the machine comes into contact with food ingredients like sugar syrup, flavoring, and colorants, cleanliness is critical to maintaining both the quality of the product and the longevity of the machine. A build-up of residue or sugar syrup can lead to clogs, inefficiencies, and potential contamination of the lollipops.

Daily Cleaning: After each production cycle, thoroughly clean the machine, especially the mixing chambers, nozzles, and molds. Use food-safe cleaning agents that won't damage the components and follow the machine's recommended cleaning procedures.

Weekly Deep Clean: A more thorough deep cleaning should be conducted weekly to remove any accumulated residue in hard-to-reach places. This might include disassembling parts like the cooling system or the packaging sections to clean them thoroughly.

By maintaining cleanliness, you prevent issues like sticky residues that can disrupt the operation of the machine or degrade the quality of the candy being produced.

2. Lubrication of Moving Parts

For optimal machine performance, it is essential to regularly lubricate the moving parts such as gears, motors, and conveyors. Proper lubrication reduces friction, minimizes wear, and ensures smoother operation. Lack of lubrication can lead to increased mechanical resistance, overheating, and even machine failure over time.

Lubrication Schedule: Follow the manufacturer's guidelines for lubrication intervals, typically at regular intervals, such as every 100 hours of operation or as recommended in the manual.

Lubricants: Use the right type of lubricant recommended by the machine manufacturer. Using incorrect or incompatible lubricants can cause damage to seals and bearings, potentially reducing the lifespan of critical parts.

3. Inspection of Electrical Components

The electrical components of the Automatic Rainbow Lollipop Machine are integral to its operation. Regular inspections and maintenance of wiring, sensors, controllers, and motors are crucial for identifying potential issues before they cause breakdowns.

Check Wiring and Connections: Inspect wiring for any signs of wear or damage. Loose connections can result in malfunctions or even electrical failure, leading to costly repairs.

Sensor Calibration: Periodically calibrate the sensors that monitor temperature, humidity, or other production factors. Properly calibrated sensors ensure accurate control over the candy-making process and prevent product inconsistencies.

Ensuring the electrical components are in good condition allows for uninterrupted operation and prevents unexpected downtime.

4. Monitoring and Replacing Worn-Out Parts

Over time, certain components of the Automatic Rainbow Lollipop Machine will naturally experience wear and tear. Monitoring the machine for signs of wear and replacing worn-out parts promptly is essential for maintaining both efficiency and safety.

Frequent Check-ups: Keep an eye on parts like nozzles, molds, conveyor belts, and cooling fans, as these are commonly subject to wear. When you notice any degradation in performance, it's a sign that a part might need replacing.

Scheduled Replacements: Establish a scheduled replacement for high-wear components that tend to degrade after a certain number of production hours. Proactively replacing these parts before they fail can reduce unexpected downtimes.

Replacing worn-out parts at the right time minimizes the risk of larger mechanical failures and ensures that the machine runs at peak performance for longer.

5. Proper Storage and Handling

When not in use, the storage and handling of the Automatic Rainbow Lollipop Machine also play a significant role in its longevity. Ensure that the machine is stored in a dry, clean, and well-ventilated area. Excessive moisture or dirt accumulation can lead to corrosion, while extreme temperatures can affect the performance of sensitive components.

Covering the Machine: If the machine is stored for long periods, consider covering it with protective material to shield it from dust, moisture, and other environmental factors.

Avoid Overloading: Always operate the machine within its capacity limits. Overloading the machine can cause stress on its components, leading to quicker wear and potential breakdowns.

Proper storage and handling contribute to the machine's ability to function efficiently when needed and extend its operational life.

6. Regular Software and Firmware Updates

For machines with digital controls or automated systems, staying on top of software or firmware updates is crucial. Manufacturers may release updates to improve functionality, fix bugs, or enhance the machine's efficiency. Failing to keep the software up to date could result in the machine operating at suboptimal levels or encountering issues that could affect its longevity.

Software Upgrades: Follow the manufacturer's recommendations for updating software to ensure that the machine benefits from any new improvements or fixes.

Technical Support: Stay in contact with the manufacturer or service provider to receive the latest updates or troubleshooting advice for any issues that might arise.

Keeping the machine's software current can prevent malfunctions and help keep the equipment functioning smoothly for a longer period.

7. Staff Training and Operating Procedures

Another often-overlooked aspect of machine maintenance is proper staff training. Operators who are well-trained in how to use, clean, and maintain the machine will have a significant impact on its performance and lifespan. Untrained or careless handling can lead to errors in operation, mismanagement of settings, or improper cleaning procedures, which can negatively affect the machine.

Operational Training: Provide thorough training to all operators, ensuring they understand the machine's functions, maintenance requirements, and safety protocols.

Maintenance Protocols: Develop a comprehensive maintenance schedule that includes daily, weekly, and monthly checks. Ensure all staff members are aware of these protocols and follow them consistently.

Proper training ensures that the machine is operated with care, preventing accidents and ensuring that routine maintenance tasks are carried out correctly.

8. Establish a Routine Maintenance Program

One of the best ways to ensure the longevity of your Automatic Rainbow Lollipop Machine is to set up a routine maintenance program. Establishing a schedule for inspections, cleanings, part replacements, and lubrication can help identify potential issues before they escalate into serious problems. Working with a qualified technician or the machine's manufacturer for periodic reviews will ensure that the machine is always in optimal condition.

Maintenance Logs: Keep detailed records of all maintenance activities. This log helps track the machine's condition over time and serves as a reference for when parts were last replaced or cleaned.

A well-planned maintenance program helps extend the machine's operational life, reducing the need for expensive repairs or premature replacement.

The Future of Automatic Candy Machines

The future of automatic candy machines is bright, with ongoing advancements in technology, innovation, and consumer demand for more efficient, customizable, and sustainable candy production. As the candy industry continues to grow and evolve, automatic candy machines, including those for rainbow lollipops, are becoming more sophisticated, meeting both the challenges of high-volume production and the need for intricate design options.

1. Integration of Artificial Intelligence and Automation

One of the most exciting developments in the future of automatic candy machines is the integration of artificial intelligence (AI) and advanced automation. AI has the potential to revolutionize candy production by offering machines the ability to learn from past production runs and optimize future batches. AI-powered machines can analyze data from various production stages, adjust settings for better efficiency, and predict when maintenance is needed.

This technology will not only improve the speed and quality of production but also reduce human error and waste. Automation, combined with AI, will make candy production more flexible and adaptive to changes in demand, customer preferences, and market trends. For example, automatic machines could adjust flavor profiles or color designs in real-time based on consumer feedback or sales data, enabling manufacturers to offer personalized candy experiences.

2. Enhanced Customization and Personalization

As consumer demand shifts toward more personalized products, candy manufacturers will need to find ways to offer customized candy options. The future of automatic candy machines lies in their ability to create more diverse, customizable candy products that cater to individual tastes and preferences. This includes offering unique flavors, colors, shapes, and designs for candies like rainbow lollipops.

Machines are becoming increasingly capable of producing candies with personalized imprints, logos, or names, making them perfect for special events, corporate gifts, and seasonal promotions. The future could also bring machines capable of producing multi-flavored or multi-textured lollipops or candies with unique filling or topping combinations, all while maintaining high-quality standards and speed of production.

3. Sustainability and Eco-Friendly Manufacturing

Sustainability is a key concern for many industries, and the candy production sector is no exception. Eco-friendly automatic candy machines will play a vital role in the future of candy production, as manufacturers are increasingly focused on reducing their environmental footprint. These machines will use energy-efficient technologies to minimize power consumption and sustainable materials for both production and packaging.

Additionally, innovations in waste reduction will ensure that less raw material is wasted during the candy-making process. Future machines will likely include better recycling systems that allow manufacturers to reuse excess candy or materials that would otherwise be discarded. This is not only beneficial for the environment but also helps reduce production costs.

4. Faster Production with High Precision

The demand for faster production without sacrificing quality will drive the development of high-speed candy machines in the future. Automatic candy machines will become more precise and faster, capable of producing large quantities of candy, such as rainbow lollipops, in a shorter time frame. This will be especially important as candy manufacturers aim to meet growing consumer demand without compromising on the quality or appearance of the final product.

Advanced technology will allow for better synchronization between various stages of production, such as mixing, molding, cooling, and packaging, ensuring a seamless, continuous operation. Machines will be able to handle large volumes while ensuring each candy piece has the perfect shape, size, and design.

5. Improved User Experience with Smart Interfaces

In the future, the user experience of operating candy machines will continue to improve. Machines will be equipped with smart interfaces that provide intuitive control, real-time monitoring, and predictive maintenance alerts. Operators will be able to easily adjust settings such as candy shape, color, and texture using touchscreens or even voice commands.

These smart interfaces will allow for a more streamlined operation, reducing the need for extensive training and improving overall production efficiency. Operators will be able to access data analytics in real-time, making it easier to spot potential issues, improve production strategies, and make decisions based on data-driven insights.

6. Integration with Other Industry Technologies

The future of automatic candy machines will see increased integration with other technologies used in the food industry. For example, candy machines could be integrated with inventory management systems, allowing for better tracking of ingredients and raw materials, reducing waste, and ensuring that production runs smoothly.

Additionally, the machines may integrate with supply chain management platforms, allowing manufacturers to better plan production schedules, reduce lead times, and improve efficiency. The future could also bring greater integration with e-commerce platforms, where consumers could place customized candy orders that directly influence production runs.

7. Advanced Quality Control and Monitoring Systems

In the future, automatic candy machines will be equipped with even more advanced quality control and monitoring systems to ensure consistency and quality at every stage of production. These systems will use sensors, cameras, and machine learning algorithms to identify defects, such as uneven shapes, inconsistent colors, or improper texture, in real-time.

By incorporating these technologies, candy manufacturers will be able to maintain higher standards of product quality and reduce waste due to defects. Additionally, these systems will help to maintain consistent production standards, ensuring that each batch of rainbow lollipops or other candies meets consumer expectations.

8. Multi-Functionality and Versatility

The future will likely bring multi-functional automatic candy machines capable of producing a wider variety of products. For instance, a single machine might be able to produce not only rainbow lollipops but also other types of hard candies, chocolates, or gummies, all while maintaining optimal efficiency.

This versatility will be highly beneficial for manufacturers looking to diversify their product offerings without investing in separate machines for each type of candy. The ability to switch between different candy types and designs with minimal downtime will make production lines more flexible and cost-effective.

The future of automatic candy machines is shaped by technological innovation, sustainability, and the demand for high-quality, customizable products. As the candy industry continues to evolve, so too will the capabilities of automatic machines, offering faster, more efficient, and environmentally friendly solutions. Manufacturers will benefit from greater customization options, improved precision, and integration with other industry technologies, ensuring they stay competitive and responsive to market demands.

At Jiangsu Flying Dragon Food Machinery Co., Ltd., we are proud to be at the forefront of this exciting future in the candy industry. Our Automatic Rainbow Lollipop Machines are designed with cutting-edge technology to meet the growing demands of modern candy manufacturing, delivering high-quality, customizable lollipops with efficiency and precision. Let us help you innovate your candy production process and lead the way in the future of confectionery manufacturing.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

Home

Home